Нова машина за производство на дървени въглища | Пещ за непрекъсната карбонизация

| Модел | SL-05 |

| Капацитет | 0,3-0,5т/ч |

| Метод на работа | Напълно непрекъснато |

| Размер на реактора | 820 мм |

| Консумация на енергия | 45kw/h |

| Размери | 28м*10м*6м |

| Тегло | 28т |

| Работно налягане | Леко отрицателно налягане |

| Срок на експлоатация | 5-8 години |

Нова машина за производство на въглища е непрекъсната пещ за коксозиране, специално разработена за карбонизиране на различни биомаси. Новият дизайн на пещта за коксозиране не само е красива по външен вид и атмосфера. А нейната конзола е добавила интелигентен цифров контролен панел. Освен това скоростта на коксоза на суровините е увеличена от първоначалните 75% до 95%. В обобщение, новият чарков машин е нисковъглероден енергоефективен оборудване с висока възвръщаемост и висока рентабилност. Свържете се с нас сега за последните консултации по него. Например, цена, доставка. Очакваме приятно сътрудничество с Вас.

Суровини за машина за производство на дървени въглища с нов дизайн

Може да обработва биомасивни суровини с размери по-малки от 10 см. Неговите суровини са отпадъци от селското стопанство и горското стопанство (оризова обвивка, дървен пелет, слама пелет, кора), плодови обвивки (кокосова черупка, плодова обвивка от маслинен плод, палмови черупки, орехова черупка, дълго паз, др.), и други (говежди тор, кости на крави, утайка) и др. Тъй като влажността на суровината е по-малка, скоростта на коксозиране е по-висока. Затова ще препоръчаме на клиентите да изберат барабанна сушилня за изсушаване на суровините. Сушилното може да поддържа влажност на суровината около 8%.

Конструкция на новата машина за производство на дървени въглища

Двойна главна пещ

Карбонизиращото основно тяло на карбонизиращата пещ приема двуцилиндрова структура. Този дизайн кара материала да се търкаля от вътрешната пещ към външната пещ в кръг. Това означава, че входът и изходът на пещта за карбонизиране на кокосови черупки са от една и съща страна.

Камера за горене

Горивната камера е изолирана с топлоизолационна каменна вата. Това също е затворено тяло на пещта. Следователно херметичността на цялата машина е добра и ефективността на карбонизация е висока. Нагревателният материал на пещта за карбонизиране на оризови люспи може да бъде въглен, дърво, дизел, природен газ, втечнен нефтен газ, биомаса и др.

PLC контролен панел

Системата за стартиране и управление беше променена от предишния шкаф за разпределение на мощността към режим на сензорен екран на plc. Клиентите могат да задават през компютъра скорост, температура, време и др.

Подсилване на пещта

Повърхността на тялото на пещта е подсилена с хоризонтален и вертикален метал от въглеродна стомана. Корпусът на пещта е обвит в корпус от неръждаема стомана. Поради това използването на новата машина за производство на дървени въглища от черупки на кокосов орех не се деформира лесно и има по-дълъг живот.

Видео на пещ за непрекъсната карбонизация на биомаса

По-долу е видео за обработка на различни суровини с биомаса пещ за коксозиране. Видеото показва ефективното и висококачествено образуване на въглища.

Параметри на новата конструкция на машината за производство на дървени въглища

Времето и температурата на карбонизация на различните суровини са различни. Следователно следните данни са само за справка.

| Модел | SL-05 | SL-10 | SL-30 | SL-50 |

| Капацитет | 0,3-0,5т/ч | 0,8-1т/ч | 2,5-3т/ч | 4,5-5т/ч |

| Метод на работа | Напълно непрекъснато | |||

| Размер на реактора | 820 мм | 1000 мм | 1300 мм | 1700 мм |

| Консумация на енергия | 45kw/h | 65kw/h | 90kw/h | 125kw/h |

| Размери | 28м*10м*6м | 33м*13м*7м | 40м*15м*8м | 50м*16м*10м |

| Тегло | 28т | 35т | 45т | 54т |

| Работно налягане | Леко отрицателно налягане | |||

| Срок на експлоатация | 5-8 години |

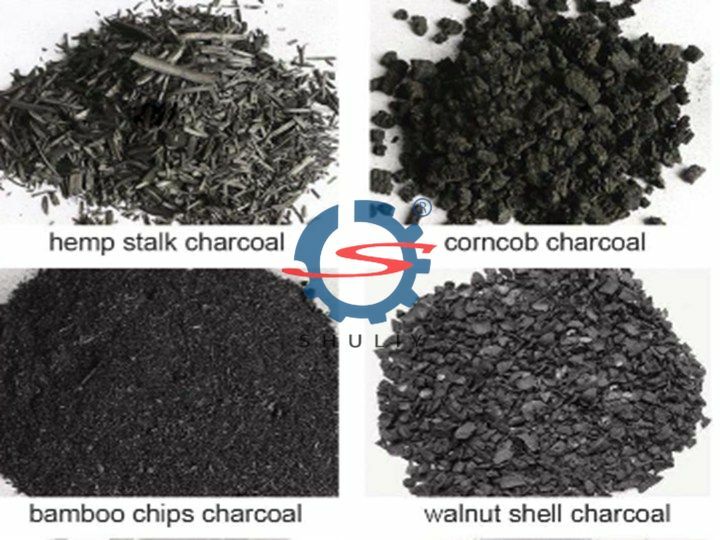

Готови продукти от био въглища

Крайните продукти на тази отлична непрекъсната пещ за карбонизация могат да бъдат различни, като въглен от кокосови черупки, въглен от дървени стърготини, въглен от черупки на палмови ядки, въглен от бамбук, въглен от оризови люспи и въглен от черупки на ядки и др.

Принцип на работа на пещта за карбонизация на дървени въглища

Процесът на карбонизация включва нагряване на органичния материал в среда с ограничен кислород. Тъй като материалът се нагрява, той започва да се разпада и да отделя летливи газове. След това тези газове се изгарят, оставяйки след себе си твърд остатък от въглерод, който е известен като въглен.

Приложения на пещ за непрекъсната карбонизация

Пещите за непрекъснато карбонизиране на въглен обикновено се използват при производството на активен въглен, който е форма на въглен, която е била обработена, за да се увеличи повърхността му и да стане по-порест. Активният въглен има широк спектър от приложения, включително обработка на вода, пречистване на въздуха и химическо разделяне.

В допълнение към използването им в производството на активен въглен, пещите за непрекъснато карбонизиране с въглен се използват и в различни други индустрии, включително производството на гориво, производството на химикали и обработката на отпадъчни материали.

Заключение

Като цяло пещта за непрекъсната карбонизация е основна част от оборудването, което играе ключова роля в производството на активен въглен и други форми на въглен. Способността му да работи непрекъснато позволява ефективно и надеждно производство, което го прави важен инструмент в широк спектър от индустрии.

Shuliy група е професионален производител на пещи за карбонизация на дървени въглища. Ние предоставяме пълен набор от машини за карбонизация, за да отговорим на вашите специфични изисквания. Заповядайте да се свържете с нашите експерти, за да стартирате бизнеса си възможно най-скоро.