Ротационна таблетна преса за наргиле | Машина за производство на дървени въглища за шиша

| Модел | SL-RS21 |

| Количество перфоратори (комплекти) | 21 |

| Максимално налягане на таблетката (kn) | 120 |

| Максимална дълбочина на пълнене (mm) | 16-28 |

| Дебелина на таблетката (mm) | 8-15 |

| Скорост на въртене на купола (об/мин) | 30 |

| Макс. изход (бр/ч) | 30000-40000 |

| Мощност на двигателя (kw) | 7.5 |

| Общ размер (mm) | 800*900*1650 |

| Тегло на машината (кг) | 1500 |

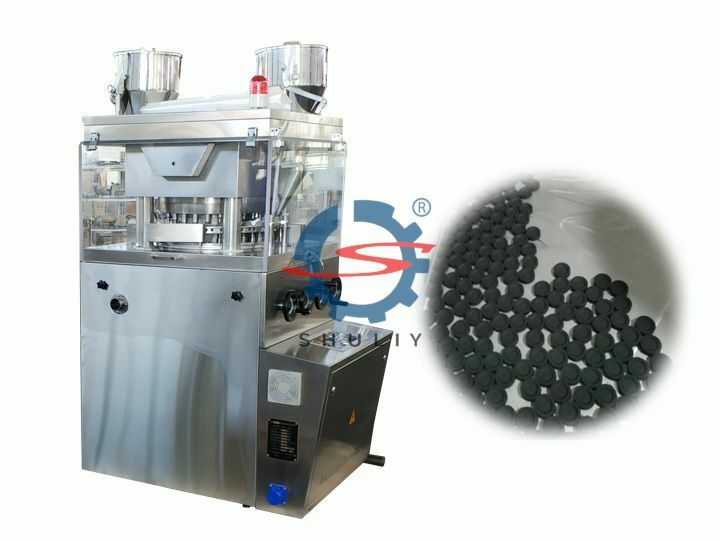

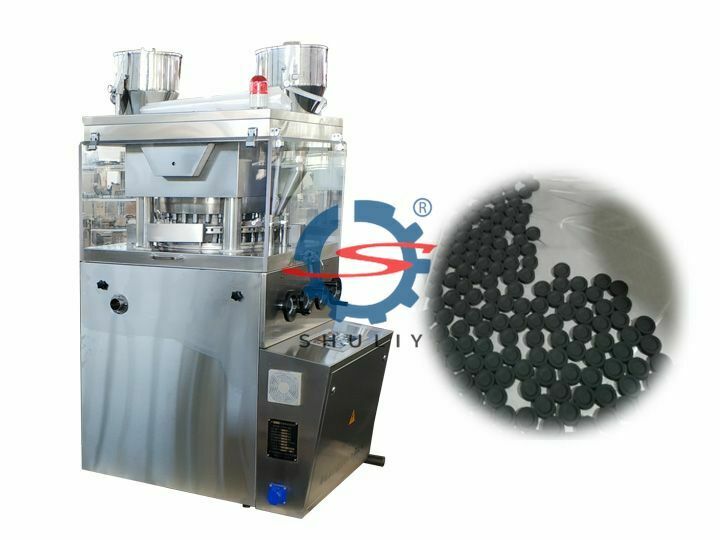

Rotary hookah coal tablet press е машина за производство на шиша въглени с висока ефективност. За разлика от обикновения машини за бутилка шиша въглена, производството на rotary tablet press е 3 пъти по-голямо от обикновения тип. Тоест, еквивалентно на 2-3 нормални машини за таблетиране на въглена прах. Затова rotary hookah charcoal tableting machine има висока икономическа стойност. Shuliy Мachine не само може да направи правилния производствен план за вас. Освен това предлагаме услуга за персонализиране на машина. Ако искате да получите цената на продукта, моля оставете ни съобщение. И ще отговорим възможно най-скоро.

Суровини за ротационна машина за таблетиране на въглен за наргиле

The raw materials of the hookah charcoal production line are various carbon powders. For example, coconut shell charcoal powder, fruit charcoal powder, bamboo charcoal powder, charcoal powder, etc. The rotary hookah charcoal machine is to press these carbon powders into hookah charcoal sheets of various shapes. In addition to pressing round tablets, it can also press special-shaped tablets, special tablets, square tablets, ring tablets, etc. Hookah charcoal production is not only adjustable in diameter. And the size, strength, and hardness of the carbon sheets are produced according to the customer’s requirements.

Основен принцип на машината за производство на въглища за наргиле

Причината, поради която ротационната преса за въглен за наргиле е ефективна и висококачествена. Заради уникалната си система за формиране на въглен за наргиле. Смело изоставя традиционния начин на удари нагоре и надолу. Той умело използва горни и долни удари по протежение на извитата писта, за да притиска естествено във високите и долните точки. Предимството на този дизайн е, че всяко парче въглен може да издържи еднакво налягане. Това е и най-ценната част от реформата на машината за производство на въглен за наргиле.

Конструкция на ротационна таблетна преса за наргиле

Структурата му включва захранващ порт, изпускателен порт, матрица (горна, средна и долна), двигател, двигател за забавяне, притискаща ролка и приемна тава. Неговата електроцентрала е затворена под тялото. Тестовата машина и ежедневната поддръжка трябва да проверят двигателя и той може да бъде проверен с ключа. Конструкцията на цялата ротационна преса за таблетки е много компактна и спестява място.

Мухъл

Диаметърът на матрицата, шаблонът и текстът могат да бъдат персонализирани. Следователно произведените въглища за наргиле са по-отличителни и в същото време имат по-широка аудитория. Корпусът на машината и материалът на формата са издръжлива неръждаема стомана. Така че почти няма износващи се части и има експлоатационен живот от 8-10 години.

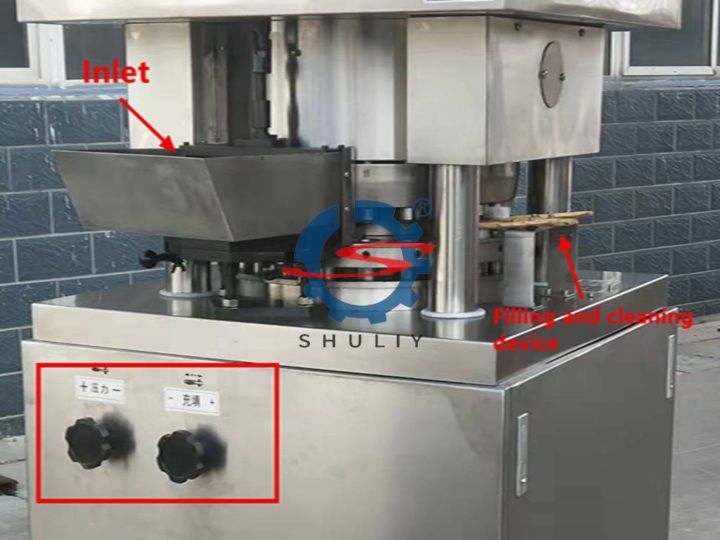

Вход

Картината вдясно показва входа за захранване и бутона за варене на машината за формоване на въглища Hully. Позицията на захранващия отвор на машината за въглен за наргиле е много подходяща. Следователно е много удобно за използване и откриване от операторите. А бутоните отстрани на машината могат да регулират налягането и броя на пълненията.

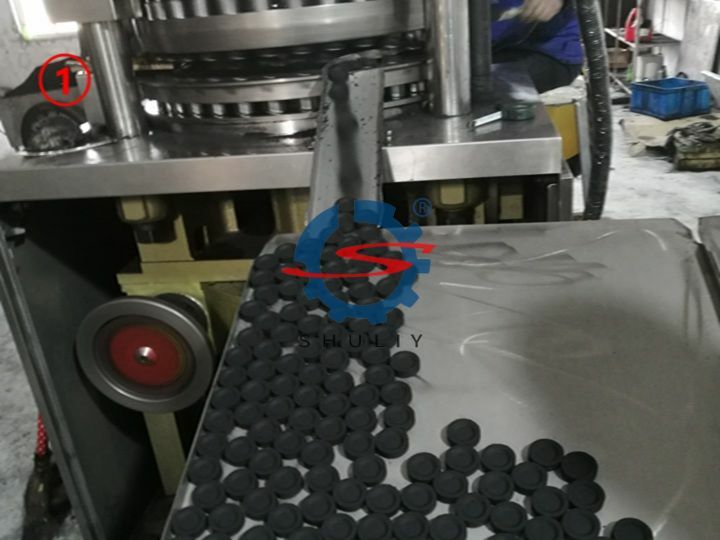

Изход

There is a baffle plate at the outlet. so that the hookah charcoal is collected in an orderly manner. Furthermore, we equip our customers with a catch tray. It facilitates the operation of the drying part of the hookah and the operation of the ring-shaped hookah charcoal sorting machine.

Параметри на ротационна таблетна преса за наргиле

Ние произвеждаме различни модели преси за таблетиране с въглен. Перфораторът 21 е един от най-продаваните у нас. По-долу са параметрите на машината за таблетки с 21 удара с диаметър 30 мм.

| Модел | SL-RS21 |

| Количество перфоратори (комплекти) | 21 |

| Максимално налягане на таблетката (kn) | 120 |

| Максимална дълбочина на пълнене (mm) | 16-28 |

| Дебелина на таблетката (mm) | 8-15 |

| Скорост на въртене на купола (об/мин) | 30 |

| Макс. изход (бр/ч) | 30000-40000 |

| Мощност на двигателя (kw) | 7.5 |

| Общ размер (mm) | 800*900*1650 |

| Тегло на машината (кг) | 1500 |

Видео за най-добрата таблетка за шиша с кокосови въглища

Чрез видеото по-долу можете ясно да разберете процеса на производство и опаковане на въглен за наргиле.

Какви са предимствата на пресата за таблетки с въглен за наргиле?

- Приемете PLC интелигентен контролен панел. Дебелината на въглищната таблетка за наргиле може лесно да се регулира чрез регулиране на скоростта.

- Автоматичното устройство за пълнене на машината за производство на въглен за наргиле може лесно да контролира скоростта.

- Цялата машина е изработена от неръждаема стомана, лесна за почистване и има дълъг експлоатационен живот.

- Наклонът на изпускателния отвор е проектиран разумно, така че въглищата за наргиле да се плъзгат естествено надолу, без да повредят листа въглен за наргиле.

- Въгленът за наргиле се поставя върху подаващото устройство от неръждаема стомана. Не само удобни за сушене, но и удобни за машина за опаковане на въглен за шиша опаковка.

- Когато работи, шумът е малък, налягането е голямо и свръхналягането спира, за да се избегне повреда на машината.

Дисплей за въглен за наргиле