สายการผลิตถ่านอัดก้อน

| ยี่ห้อ | ชูลี่ |

| วัตถุดิบ | ท่อนไม้ ขี้เลื่อย แกลบ กะลามะพร้าว ไม้ไผ่ ฯลฯ |

| อุปกรณ์หลัก | เตาถ่าน, เครื่องอบผ้า, เครื่องอัดก้อนถ่าน, เครื่องผสมผง, เครื่องบด, เครื่องบรรจุภัณฑ์ |

| การรับประกัน | หนึ่งปี |

สายการผลิตถ่านอัดแท่ง คือโรงงานผลิตถ่านบาร์บีคิว ถ่านชิชา ถ่าน ถ่านไม้ ถ่านกะลามะพร้าว ฯลฯ และวัตถุดิบของเครื่องทำถ่านสามารถหลากหลาย เช่น ไม้ไผ่ ท่อนไม้ กะลามะพร้าว แกลบ ขี้เลื่อย ฯลฯ ดังนั้น ลูกค้าที่ลงทุนในสายการผลิตเครื่องอัดถ่าน จึงไม่ต้องกังวลกับการจัดหาวัตถุดิบมากเกินไป เนื่องจากวัตถุดิบมีหลากหลายและราคาถูก

ในฐานะผู้จำหน่ายอุปกรณ์ถ่านมืออาชีพ เราสามารถให้คำแนะนำที่เหมาะสมสำหรับการผลิตถ่านของคุณเพื่อช่วยให้การผลิตมีประสิทธิภาพ โดยสรุป เรายินดีที่จะช่วยคุณเริ่มต้นธุรกิจการทำถ่านอัดก้อนโดยเร็วที่สุด และเราจะให้ราคาที่ดีแก่คุณ

วัตถุดิบของสายการผลิตถ่านอัดก้อน

วัตถุดิบสำหรับสายการผลิตถ่านมีหลากหลายมาก ไม่เพียงแต่ท่อนไม้ ไม้ไผ่ ไม้ผล แต่ยังรวมถึงขี้เลื่อย แกลบ เปลือกถั่ว กะลามะพร้าว เปลือกผลไม้ ฯลฯ ลักษณะของวัตถุดิบเหล่านี้คือมีลิกนินจำนวนมาก ดังนั้น ถ่านจึงเกิดขึ้นหลังจากการไพโรไลซิส ถ่านต้องถูกบดให้เป็นผงถ่านขนาด 3 มม. ด้วยเครื่องบดถ่านก่อนทำการอัดแท่ง จากนั้น ผงถ่าน สารยึดเกาะ และน้ำ จะถูกผสมให้เข้ากันในเครื่องผสมผงถ่าน ผงถ่านที่ผ่านการบำบัดด้วยวิธีนี้จะเรียบและเหนียว

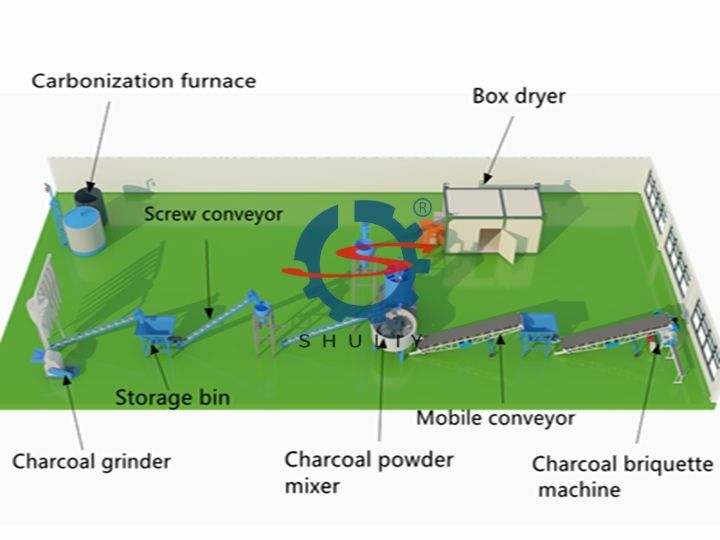

โครงสร้างสายการผลิตถ่านอัดก้อน

อันที่จริง โครงสร้างของสายการผลิตถ่านคล้ายคลึงกับสายการผลิตถ่านชิชา โครงสร้างของมันคือการคาร์บอไนซ์การบด การกวน การอัดแท่ง การอบแห้ง และการบรรจุ ขั้นตอนการทำงานของสายการผลิตถ่านอัดแท่งทั้งหมดนั้นง่ายและปลอดภัย เนื่องจากผลิตภัณฑ์สำเร็จรูปที่แตกต่างกัน จึงมีความแตกต่างอย่างมากในรายละเอียดบางประการ ด้านล่างนี้เป็นภาพวาดสายการผลิตถ่านบาร์บีคิวทั่วไป (สำหรับอ้างอิงเท่านั้น)

ชิ้นส่วนหลักของสายการผลิตถ่านอัดก้อน

ส่วนประกอบหลักของสายการผลิตถ่านอัดแท่ง ได้แก่ เครื่องคาร์บอไนซ์ เครื่องอัดถ่าน เครื่องอบถ่าน และเครื่องบรรจุถ่าน นี่คือข้อมูลโดยละเอียดเกี่ยวกับแต่ละเครื่อง

อันที่จริง การเลือกอุปกรณ์เกี่ยวข้องกับวัตถุดิบของลูกค้าเป็นอย่างมาก ตัวอย่างเช่น หากคุณต้องการใช้ท่อนไม้หรือไม้ไผ่เพื่อทำถ่านอัดแท่งรูปทรง คุณต้องใช้เตาคาร์บอไนซ์แบบยก เพื่อคาร์บอไนซ์วัตถุดิบจำนวนมาก แต่ถ้าวัตถุดิบของคุณเป็นวัสดุขนาดเล็ก เช่น ขี้เลื่อยหรือกะลามะพร้าว คุณต้องเลือกเตาคาร์บอไนซ์แบบต่อเนื่อง

ประการที่สอง เครื่องขึ้นรูปถ่าน คุณสามารถเลือกเครื่องทำแท่งถ่านและเครื่องอัดก้อนถ่าน เครื่องทำแท่งถ่านสามารถผลิตแท่งถ่านกลวงรูปหลายเหลี่ยมได้ อย่างไรก็ตาม เครื่องอัดแท่งมีกำลังการผลิตที่ใหญ่กว่า

ประการที่สาม เลือกอุปกรณ์ที่เหมาะสมตามขนาดพื้นที่โรงงานของคุณ สำหรับอุปกรณ์บางอย่างที่มีฟังก์ชันเดียวกัน เนื่องจากโครงสร้างอุปกรณ์แตกต่างกันมาก รุ่นของเครื่องจะใหญ่เกินไป เครื่องนี้ไม่เหมาะกับการวางในโรงงาน จากนั้นคุณสามารถเลือกทางเลือกที่คล้ายกันได้ ตัวอย่างเช่น เรามีอุปกรณ์อบแห้งสองชนิด:ห้องอบแห้งและเครื่องอบแห้งแบบสายพาน ขนาดของห้องอบแห้งสามารถปรับแต่งได้และการติดตั้งมีความยืดหยุ่น เครื่องอบแห้งแบบสายพานเป็นรุ่นใหญ่ แต่กำลังการผลิตมีมาก

สุดท้าย เลือกเครื่องบรรจุ ตามประเภทของผลิตภัณฑ์สำเร็จรูปและความต้องการของตลาด เพื่อป้องกันความชื้นและอำนวยความสะดวกในการขนส่ง โดยทั่วไปจะใช้เครื่องปิดผนึกและตัดเพื่อบรรจุถ่านบาร์บีคิวในตลาด

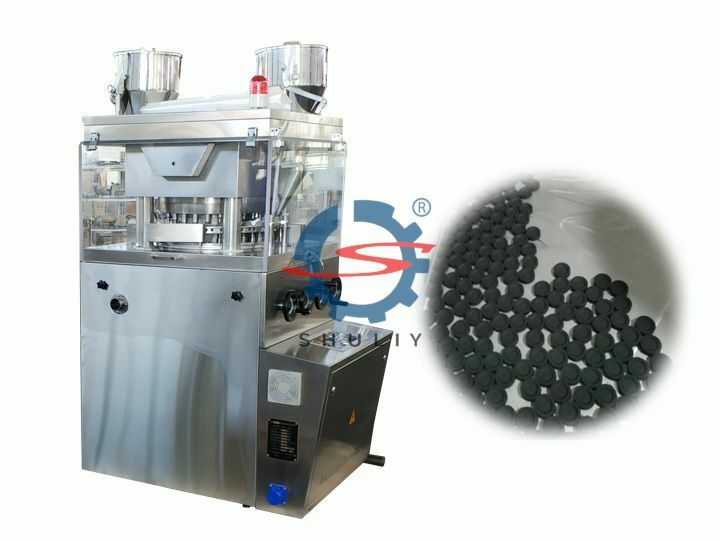

ผลิตภัณฑ์ขั้นสุดท้ายของเครื่องอัดก้อนถ่าน

อุปกรณ์ที่เกี่ยวข้องสำหรับสายการผลิตถ่านอัดก้อน

เครื่องตัด

เครื่องทำแท่งถ่าน สามารถผลิตถ่านอัดแท่งรูปทรงต่างๆ ได้ ลูกค้าสามารถใช้เครื่องตัดเพื่อตัดแท่งถ่านที่มีความยาวต่างกัน โรงงานของเรามีเครื่องตัดเมตร เครื่องตัดอินฟราเรด และหัวกัด

ไซโล

ไซโลสามารถเก็บผงถ่านได้ ซึ่งรับประกันการผลิตอย่างต่อเนื่องของโรงงานแปรรูปถ่านอัดก้อน เรามีไซโลจัดเก็บผงถ่าน ไซโลชั่งน้ำหนัก และไซโลย่อยผงถ่าน ไซโลแต่ละอันมีลักษณะเฉพาะของตัวเอง

สายพานลำเลียง

สาเหตุที่สายการผลิตประหยัดแรงงานก็เนื่องมาจากการป้อนอัตโนมัติของสายพานลำเลียง อุปกรณ์ลำเลียงทั่วไปคือการลำเลียงแบบสกรูและการลำเลียงสายพานลำเลียง สำหรับฝุ่น ให้เลือกอันแรก สำหรับบล็อก ให้เลือกอันหลัง

ถ่านคืออะไร ราคาเครื่องอัดก้อน?

เราผลิตเครื่องอัดก้อนถ่านหลากหลายชนิด เช่น เครื่องอัดถ่านหินแบบบด, เครื่องอัดก้อนถ่านแบบบด, เครื่องอัดถ่านหินแบบรังผึ้ง เป็นต้น ราคาของเครื่องจักรแบบสแตนด์อโลนหรือสายการผลิตจะได้รับผลกระทบจากปัจจัยหลายประการ ในความเป็นจริง คุณภาพคือการพิจารณาเบื้องต้นของลูกค้า ประการที่สองคือราคา แต่อย่ากังวล เราจะเสนอราคาที่แข่งขันได้แก่คุณโดยพิจารณาจากปริมาณการซื้อและความตั้งใจในการซื้อของคุณ

ประโยชน์ของถ่านอัดแท่ง

ด้วยความก้าวหน้าของวิทยาศาสตร์และเทคโนโลยีและอารยธรรมของผู้คน เราจึงให้ความสำคัญกับสิ่งแวดล้อมและสุขภาพมากขึ้นเรื่อยๆ เนื่องจากเป็นถ่านบาร์บีคิวที่เป็นที่ต้องการอย่างกว้างขวางจึงมีลักษณะดังต่อไปนี้:

1. หมุนเวียนไม่มีมลพิษ

2. ทนต่อการไหม้และไม่แตกร้าว

3. ดูดีและมีรูปทรงต่างๆ

4. ไม่สูบบุหรี่ตา ติดไฟง่าย

5. ปลอดภัยและราคาถูก