สายการผลิตก้อนถ่านหิน

| ยี่ห้อ | ชูลี่ |

| อุปกรณ์หลัก | เครื่องบดคอมโพสิตถ่านหิน, เครื่องผสม, เครื่องอัดก้อนถ่านหิน, เครื่องอบผ้า, เครื่องบรรจุภัณฑ์ |

| การรับประกัน | หนึ่งปี |

สายการผลิตถ่านอัดแท่งถ่านหิน ใช้ถ่านหินเป็นวัตถุดิบหลักเพื่อผลิตแท่งอัดแท่งถ่านไม้แท่งถ่านหิน และผลิตภัณฑ์สำเร็จรูปอื่น ๆ ผงถ่านอัดแท่งมีคุณลักษณะไม่เกิดมลพิษ เวลาการเผายาว และความต้องการตลาดสูง เครื่องอัดถ่านหินเป็นอุปกรณ์หลักใน bbq coal briquette production line โรงงานของเรามีบริการแม่พิมพ์ตามสั่งและอะไหล่เครื่องจักรเสริม โปรดแจ้งเจตนาในการซื้อของคุณ นอกจากนี้ Shuliy จะมอบบริการธุรกิจคุณภาพสูงให้กับคุณ

ขั้นตอนการทำงานของสายการผลิตถ่านอัดก้อน

ขั้นตอนแรกในการดำเนินการของโครงการถ่านหินอัดก้อนคือการใช้เครื่องบดผสมถ่านหินเพื่อบดถ่านหินก้อนให้เป็นผง ประการที่สอง ใช้เครื่องผสมแบบสองเพลาเพื่อผสมผงถ่านหินและสารยึดเกาะให้เท่ากัน ขั้นตอนที่สามคือการขนส่งถ่านหินที่ถูกบดผสมแล้วไปยังไซโลเพื่อจัดเก็บ ขั้นตอนที่สี่คือการขนส่งถ่านหินที่แหลกลาญในไซโลไปยังเครื่องอัดก้อนถ่านหินเพื่อทำถ่านอัดก้อน ขั้นตอนที่ห้าคือการใช้อุปกรณ์อบแห้งเพื่อทำให้อิฐถ่านหินแห้ง สุดท้ายให้บรรจุ briquettes แห้งในบรรจุภัณฑ์พลาสติก

โครงสร้างการทำถ่านอัดก้อน ปลูก

สายการผลิตถ่านอัดแท่งถ่านหินค่อนข้างเรียบง่ายในโครงสร้าง ดังนั้นจึงต้องการอุปกรณ์น้อยมาก วัตถุดิบที่จำเป็นสำหรับสายการผลิตถ่านอัดแท่งส่วนใหญ่คือถ่านหิน วัตถุดิบของมันยังสามารถเป็นถ่านไม้ได้ กระบวนการใช้ถ่านหินเป็นวัตถุดิบเพื่อผลิตถ่านอัดแท่งคือ ถ่านหิน บด → ผสม → ใส่เข้าเครื่อง → อัดแท่ง → ปล่อยแห้ง → บรรจุหีบห่อ.

อุปกรณ์ที่เกี่ยวข้องสำหรับสายการผลิตอัดก้อนผงถ่านหิน

ต่อไปนี้จะแนะนำอุปกรณ์และฟังก์ชั่นอุปกรณ์ที่สายการผลิตถ่านอัดก้อนจำเป็นต้องใช้

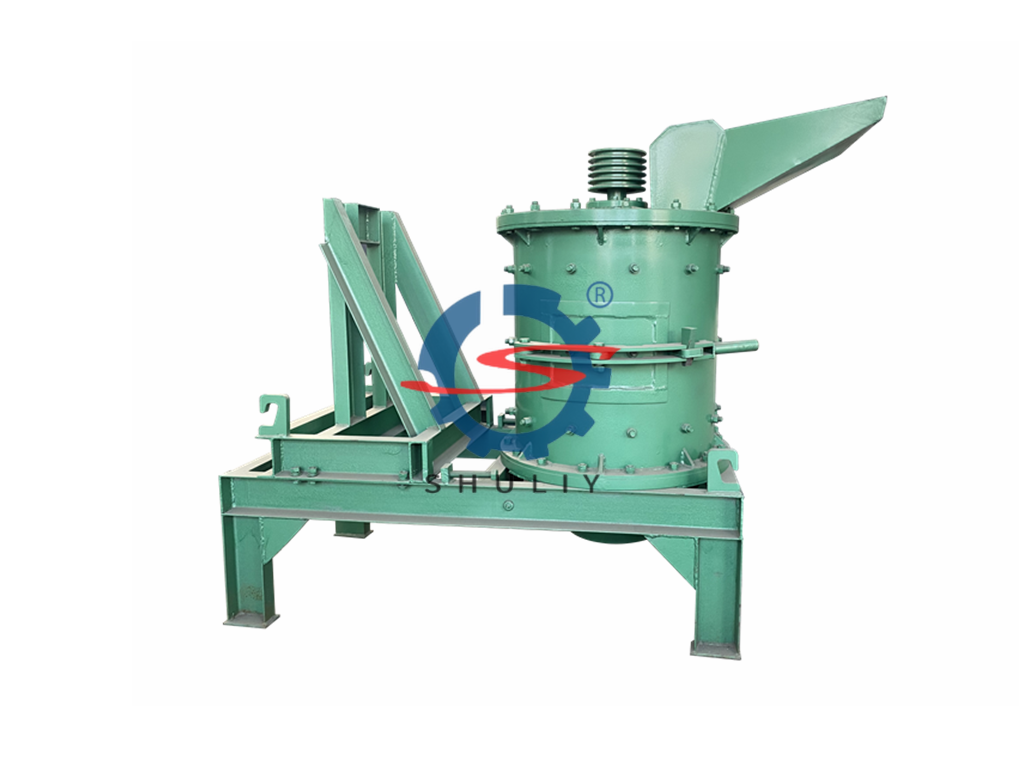

Coal composite crusher (crushing)

มันเป็น เครื่องบดหลายฟังก์ชัน ดังนั้นวัตถุดิบของมันคือถ่านหิน, หินกรวด, หินปูน, เถ้า และอื่นๆ มันสามารถบดถ่านหินให้เป็นผงถ่านหินขนาดประมาณ 2 มม. ได้อย่างรวดเร็ว.

Double shaft mixer (mixing)

ใช้โครงสร้างใบมีดแบบเกลียวคู่ ถ่านหิน สารยึดเกาะ และน้ำที่บดแล้วจะถูกกวนจนหมดในถังกวน จากนั้นจึงตกลงจากช่องระบายไปยังสายพานลำเลียง

Charcoal powder silo (feeding)

ถ่านหินที่บดผสมแล้วจะถูกเก็บไว้ในไซโล มีพอร์ตระบายและวาล์วอยู่ใต้ไซโล ดังนั้นลูกค้าจึงสามารถปล่อยวัตถุดิบสำหรับสายการผลิตอิฐได้ด้วยตนเอง กล่าวโดยสรุป ไซโลคือการรับประกันการผลิตอย่างต่อเนื่อง

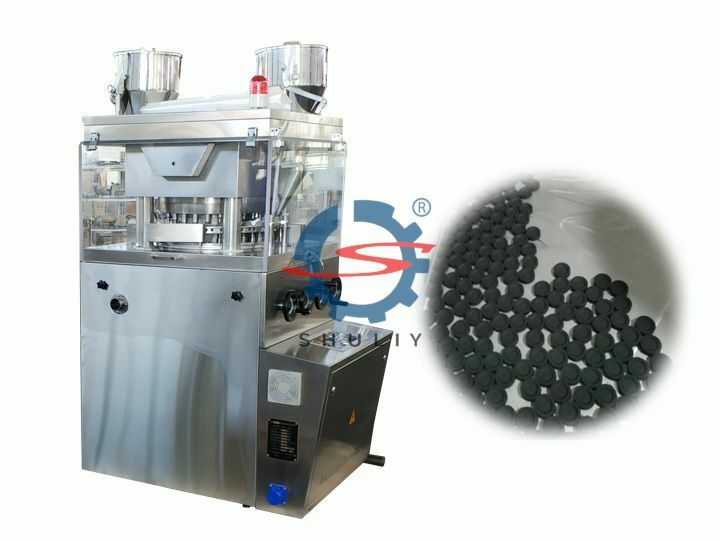

Coal making machine (briquette)

It pre-presses the coal powder into a mold. After that, it is completed by punching the needle and re-pressing the pressing block.

Dryer (drying)

It is used to quickly dry charcoal briquettes. What’s more, we have a drying room and a mesh belt dryer. These two drying equipment are often used in the briquettes production line.

Packaging machine (packaging)

Briquettes and coal sticks can be packaged with sealing and cutting machines. It adopts a heat shrinking process, which is convenient and quick. We also have a quantitative packaging machine to choose from.

ราคาสายการผลิตถ่านหินอัดก้อน

เนื่องจากความต้องการของลูกค้าที่แตกต่างกัน สายการผลิตจึงแตกต่างกัน ดังนั้นราคาเส้นราคาของเครื่องอัดถ่านหินที่แตกต่างกันจึงแตกต่างกัน เราต้องการทราบอุปกรณ์เฉพาะที่คุณต้องการซื้อ หรือเราสามารถจัดเตรียมโปรแกรมสายการผลิตที่เหมาะสมให้กับคุณได้ สรุปคือเราต้องแก้ไขปัญหาตามสถานการณ์จริงของลูกค้าของเรา ดำเนินการทันที ติดต่อเรา เพื่อดำเนินธุรกิจ

ขายเครื่องทำถ่านหิน

เราผลิตเครื่องอัดถ่านหินแบบรวงผึ้ง เครื่องอัดถ่านบาร์บีคิว และเครื่องปั้นก้อนถ่านหิน ดังนั้นจึงสามารถตอบสนองความต้องการการผลิตของลูกค้าที่แตกต่างกัน แต่ยังตอบสนองความต้องการในการซื้อของผู้บริโภคที่แตกต่างกันด้วย สายการผลิตเครื่องทำถ่านหิน Shuliy Machinery มีหลากหลายรุ่น นอกจากนี้โรงงานของเรายังให้บริการลูกค้าด้วยการปรับแต่งผลิตภัณฑ์ หากคุณมีคำถามใด ๆ โปรดฝากข้อความไว้ แล้วเราจะช่วยเหลือคุณโดยเร็วที่สุด