Kiwanda cha Briquette cha Mkaa wa Nazi

| Chapa | Shuliy |

| Malighafi | Ganda la nazi |

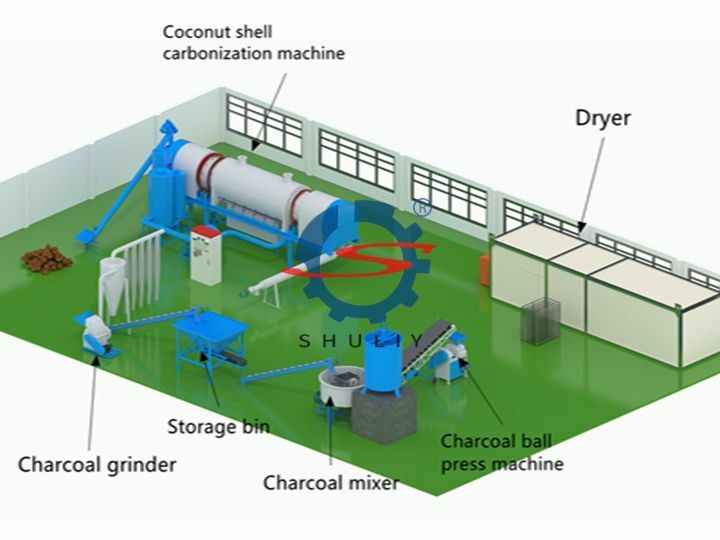

| Vifaa kuu | Tanuru ya kaboni, kikaushio, mashine ya kuchapisha mpira wa mkaa, mashine ya ufungaji |

| Udhamini | Mwaka mmoja |

Kiwanda cha briquette za makaa ya nazi ni kituo kinachozalisha briquettes rafiki wa mazingira zinazotengenezwa kutoka kwa ganda la nazi. Miongoni mwao, mashine ya briquette za ganda la nazi ndiyo vifaa vya kutengeneza katika mstari wa uzalishaji. Inaweza kubana aina zote za vifaa vya unga kuwa vizuizi. Vile vile, mfano wa kawaida ni, kugandisha unga wa makaa, kugandisha madini, kugandisha gypsum ya desulfurization, kugandisha makaa ya coke, vipande vya chuma, kugandisha slag mbalimbali za metal, n.k. Mstari wa utengenezaji wa briquette za makaa ya nazi una sifa za uendeshaji rahisi, gharama ya chini, na faida kubwa. Ikiwa una hamu ya mradi huu, tafadhali wasiliana nasi na tutajaribu kadri tuwezavyo kuboresha biashara yako ya makaa.

Malighafi ya mstari wa uzalishaji wa briquette ya mkaa

Malighafi ya mashine ya briquette za makaa inaweza kuwa unga wa ganda la nazi, unga wa sawdust, unga wa pumba za mchele, unga wa makaa, n.k. Malipo yanarejelea madini na vifaa vingine vya katalis vinavyoongezwa kwenye tanuru ya kuyeyusha. Chuma cha madini, billeti, chuma cha panya, kampuni za chuma cha kukarabati, chuma na chuma, faini za madini, makaa ya coke, coke, na ferroalloys zote zinahesabiwa kama malipo.

Sehemu kuu za mmea wa briquette ya mkaa wa nazi

Mstari wa uzalishaji wa briquette za makaa ya ganda la nazi unajumuisha mashine ya kupigia, sanduku la kuhifadhi, mlinzi wa unga wa kaboni, sanduku la usambazaji, mashine ya briquette ya unga wa kaboni, dryer ya ukanda wa mesh wa kuendelea, mashine ya kufunga. Aidha, kifaa cha usafirishaji cha kati pia ni muhimu. Chini nitazingatia mlinzi wa toner, mashine ya briquette ya unga wa kaboni, na dryer. Kwa sababu ni kipengele muhimu kinachoathiri ubora wa mpira.

Mchanganyiko wa unga wa mkaa wa nazi

Kwa ujumla, mkaa unaweza kupata takriban 3mm ya unga wa kaboni baada ya kupita kwenye kinu cha nyundo. Hata hivyo, kadri unga wa kaboni unavyoongezeka, ndivyo athari ya uundaji wa briquette ya mkaa wa nazi inavyoongezeka. Kwa hiyo, kwa upande mmoja, matumizi ya kinu ya gurudumu la mkaa inaweza kufanya nyenzo kuwa maridadi zaidi na kusaidia kuunda. Kwa upande mwingine, baada ya poda ya kaboni, binder na maji huchochewa na rolling, nyenzo zinaweza kufungia maji kikamilifu na kuboresha viscosity ya ndani ya molekuli.

Mkaa vyombo vya habari mpira mashine

Mashine ya kutengeneza unga wa mkaa wa Nazi ndiyo kifaa kikuu katika mstari mzima wa uzalishaji. Inatumia kanuni ya harakati ya jamaa ya rollers ili kutoa malighafi. Pia, kipenyo cha roll na aina ya ngozi inaweza kubinafsishwa. Briquette iliyoundwa inaweza kukusanywa moja kwa moja na kukaushwa kwenye ukanda wa conveyor kwenye sehemu ya chini ya mashine.

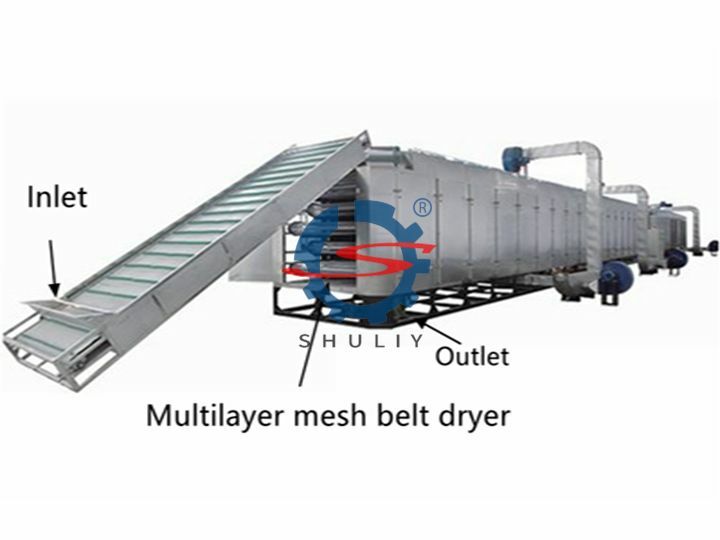

Kikausha ukanda wa matundu kwa mmea wa mkaa wenye umbo

Kwa sababu ya maudhui ya juu ya maji ya briquette ya unga wa kaboni iliyotengenezwa hivi karibuni, haiwezi kutimiza mahitaji ya matumizi. Kwa hivyo, tunapendekeza kutumia dryer ya ukanda wa mesh kwa ajili ya kukausha. Dryer ya ukanda wa mesh hutumia ukanda wa kubebea wa chuma kufikia kukausha kwa pande zote za mipira ya makaa. Aidha, ukanda wa mesh wa safu nyingi unatumika kwa kukausha kwa kurudiarudia ili kufikia uendeshaji wa kuendelea wa masaa 24.

Maombi na faida za mkaa wa nazi

Mkaa wa nazi, pia unajulikana kama mkaa wa ganda la nazi, una matumizi na manufaa kadhaa. Baadhi ya mashuhuri zaidi ni pamoja na:

- Mafuta ya barbeque: Mkaa wa nazi ni mafuta maarufu kwa choma na kuchoma kwa sababu ya utoaji wake wa joto la juu na muda mrefu wa kuchoma.

- Uchujaji wa maji: Mkaa wa nazi mara nyingi hutumiwa katika mifumo ya kuchuja maji kwa sababu ya uwezo wake wa kuondoa uchafu na kuboresha ladha ya maji.

- Kusafisha hewa: Mkaa wa nazi pia unaweza kutumika katika mifumo ya kusafisha hewa ili kuondoa uchafu na kuboresha ubora wa hewa.

- Kilimo: Mkaa wa nazi pia hutumika kama kiyoyozi na mbolea ya udongo, kwani huweza kuboresha muundo wa udongo, upenyezaji hewa, na uwezo wa kuhifadhi maji.

- Michakato ya viwanda: Mkaa wa nazi hutumika katika michakato mbalimbali ya viwanda kama vile madini, tasnia ya kemikali, na tasnia ya sukari.

- Chanzo cha kaboni cha kaboni iliyoamilishwa: Mkaa wa nazi ni chanzo cha kaboni iliyoamilishwa ambayo hutumika kusafisha, kuondoa kafeini, kusafisha gesi na kusafisha maji.

- Inayoweza kufanywa upya na endelevu: Mkaa wa nazi ni chanzo cha nishati mbadala na endelevu kwani hutengenezwa kutokana na takataka (maganda ya nazi) na hauchangii ukataji miti.

- Kiasi kidogo cha majivu: Mkaa wa nazi una majivu kidogo ukilinganisha na aina zingine za mkaa, ambayo huifanya kuwa safi zaidi kutumia.

- Rafiki wa mazingira: Briketi za mkaa wa nazi huchukuliwa kuwa mafuta rafiki kwa mazingira kwani hutoa hewa kidogo ya kaboni dioksidi, methane, na gesi zingine za chafu.

Mashine ya kutengeneza unga wa madini dhidi ya mashine ya briquette ya ganda la nazi

Mashine ya briquette ya unga wa madini ni mabadiliko kwa msingi wa mashine ya briquette ya mkaa wa nazi. Kwa hivyo muundo wao wa kimsingi na kanuni ni sawa. Pia katika mmea wa briquette ya unga wa makaa ya mawe, mashine ya kutengeneza poda ya makaa ya mawe ina jukumu la kutoa unga wa madini. Kifaa kikuu cha laini yake ya uzalishaji ni kiponda kiwanja, kisambazaji, kinu cha gurudumu, mashine ya briquette ya unga wa makaa ya mawe, na mashine ya kukaushia.

- Mchakato wa uzalishaji wa mstari mzima wa uzalishaji wa briquette ya poda ya makaa ya mawe ni kwamba crusher ya kiwanja kwanza inaponda makaa ya mawe.

- Pili, poda ya madini hulishwa ndani ya kichanganyaji poda ya madini kupitia kilisha na kuchanganywa na kifunga na maji sawasawa.

- Tatu, poda ya madini iliyochakatwa hukandamizwa ndani ya mipira na mashine ya briquette ya unga wa madini.

- Hatimaye, mipira ya poda ya madini hukaushwa na mashine ya kukausha.

Kiwanda cha briquette ya mkaa wa Nazi kinauzwa

Shuliy Mashine inazalisha aina zote za vifaa vya uzalishaji mkaa. Mbali na kuuza mistari ya uzalishaji wa briquette za poda ya kaboni, pia tunauza mistari ya uzalishaji wa mashine za mkaa, mistari ya uzalishaji wa mkaa wa shisha, mistari ya uzalishaji wa makaa ya mawe yaliyosagwa, nk. Tutakupa suluhisho zinazofaa za uzalishaji ili kufaidika sana na mradi wako. Wasiliana nasi kwa maelezo zaidi na bei bora.

Jinsi ya kutengeneza briquette ya mkaa wa nazi?

Ili kutengeneza briketi za makaa ya nazi, utahitaji vifuu vya nazi, vyombo vya habari vya briquette ya mkaa, na binder (kama vile wanga wa mahindi au unga wa muhogo). Hapa kuna hatua za msingi za kutengeneza briketi za mkaa:

- Ponda maganda ya nazi vipande vidogo kwa kutumia nyundo au mashine.

- Kausha maganda ya nazi kwenye jua au kwenye kiondoa maji ili kuondoa unyevu wowote.

- Saga maganda yaliyokaushwa ya nazi kuwa unga laini kwa kutumia grinder.

- Changanya poda ya ganda la nazi na kiasi kidogo cha binder (takriban 5% ya uzito wote wa unga) hadi iwe na uthabiti wa unga.

- Tumia mashine ya briquette ya ganda la nazi kutengeneza mchanganyiko kuwa briketi.

- Kausha briquette kwenye jua au kwenye dehydrator hadi ziwe kavu kabisa.

- Briketi zako za makaa ya nazi sasa ziko tayari kutumika.

Ni muhimu kutambua kwamba utengenezaji wa mkaa ni mchakato hatari na unapaswa kufanywa kwa tahadhari sahihi za usalama na mwongozo wa kitaalamu. Shuliy Machinery ni mtengenezaji wa mmea wa briquette ya mkaa wa nazi na uzoefu mzuri na uwezo mkubwa. Ukitaka kuanzisha biashara yako ya kutengeneza mkaa wa nazi, wasiliana nasi kwa maelezo zaidi.