Coconut Charcoal Briquette Plant

| Brand | Shuliy |

| Raw material | Coconut shell |

| Main equipment | Carbonization furnace, dryer, charcoal ball press machine, packaging machine |

| Warranty | One year |

Coconut charcoal briquette plant is a facility that produces eco-friendly briquettes made from coconut shells. Among them, the coconut shell briquette machine is the forming equipment in the production line. It can press all kinds of powdery materials into blocks. The most common ones are, for example, coal powder molding, ore powder molding, desulfurization gypsum molding, coke powder molding, iron filings, various metal slag molding, etc. The coconut charcoal briquette manufacturing line has the features of easy operation, low cost, and high return. If you are interested in this project, please contact us and we will try our best to booming your charcoal business.

Raw material of charcoal briquette production line

The raw material of the charcoal briquette machine can be coconut shell powder, sawdust powder, rice husk powder, coal powder, etc. Charge refers to the ore and other catalytic materials added to the smelting furnace. Iron ore, billets, pig iron, recycling scrap iron companies, scrap iron and steel, ore fines, coking coal, coke, and ferroalloys all belong to the charge.

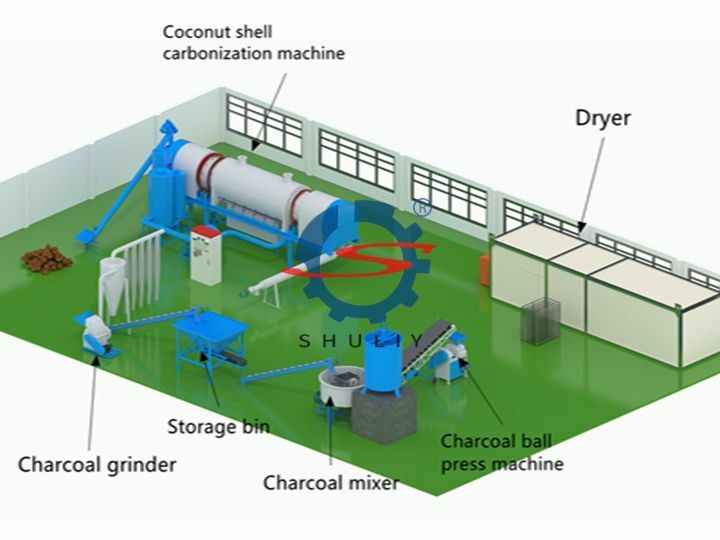

Main parts of the coconut charcoal briquette plant

The coconut shell charcoal briquette production line includes a hammer mill, storage bin, carbon powder wheel mill, distribution bin, carbon powder briquette machine, continuous mesh belt dryer, packaging machine. In addition, the intermediate conveying device is also essential. Below I will focus on the toner wheel mill, carbon powder briquetting machine, and dryer. Because they are an important factor affecting the quality of the ball.

Generally, charcoal can get about 3mm of carbon powder after passing through the hammer mill. However, the higher the fineness of the carbon powder, the better the forming effect of the coconut charcoal briquette. Therefore, on the one hand, the use of a charcoal dust wheel mill can make the material more delicate and help to shape it. On the other hand, after the carbon powder, binder and water are stirred by rolling, the material can fully lock the water and improve the internal viscosity of the molecule.

The Coconut charcoal powder forming machine is the core equipment in the whole production line. It uses the principle of relative movement of the rollers to extrude the raw materials. Also, the roll diameter and roll skin type can be customized. The formed briquette can be directly collected and dried on the conveyor belt at the lower part of the machine.

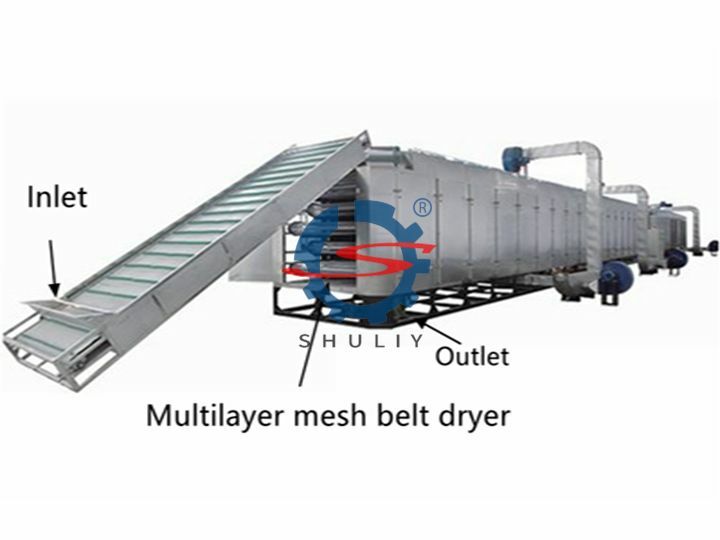

Mesh belt dryer for shaped charcoal plant

Due to the high water content of the carbon powder briquette just made, it cannot meet the requirements for use. Therefore, we recommend using a mesh belt dryer for drying. The mesh belt dryer uses a metal mesh conveyor belt to achieve all-around drying of charcoal balls. Moreover, the multi-layer mesh belt is flowed reciprocating drying to achieve 24-hour continuous operation.

Applications and benefits of coconut charcoal

Coconut charcoal, also known as coconut shell charcoal, has a number of applications and benefits. Some of the most notable include:

- Barbecue fuel: Coconut charcoal is a popular fuel for barbecues and grilling because of its high heat output and long burn time.

- Water filtration: Coconut charcoal is often used in water filtration systems because of its ability to remove impurities and improve the taste of water.

- Air purification: Coconut charcoal can also be used in air purification systems to remove impurities and improve air quality.

- Agriculture: Coconut charcoal is also used as a soil conditioner and fertilizer, as it can improve soil structure, aeration, and water holding capacity.

- Industrial processes: Coconut charcoal is used in various industrial processes such as metallurgy, chemical industry, and sugar industry.

- Carbon source for activated carbon: Coconut charcoal is a source of activated carbon which is used for purification, decaffeination, gas purification, and water purification.

- Renewable and sustainable: Coconut charcoal is a renewable and sustainable fuel source as it is made from a waste product (coconut shells) and does not contribute to deforestation.

- Less ash: Coconut charcoal has less ash compare to other type of charcoal, which makes it cleaner to use.

- Environmentally friendly: Coconut charcoal briquettes are considered as an eco-friendly fuel as they emit less carbon dioxide, methane, and other greenhouse gases.

Mineral powder forming machine vs coconut shell briquette machine

The mineral powder briquette machine is a transformation on the basis of the coconut charcoal briquette machine. So their basic structure and principle are the same. Also in the coal powder briquette plant, the coal powder forming machine plays the role of extruding the ore powder forming. The main equipment of its production line is a compound crusher, feeder, wheel mill, coal powder briquette machine, and dryer machine.

- The production process of the entire coal powder briquette production line is that the compound crusher first crushes the coal.

- Secondly, the mineral powder is feed into the mineral powder mixer through the feeder and mixed with the binder and water evenly.

- Thirdly, the processed mineral powder is pressed into balls by a mineral powder briquette machine.

- Finally, the mineral powder balls are dried by a dryer machine.

Coconut charcoal briquette plant for sale

Shuliy Machinery produces all kinds of charcoal production equipment. In addition to selling carbon powder briquette production lines, we also sell charcoal machine production lines, hookah charcoal production lines, pulverized coal production lines, etc. We will provide you with suitable production solutions to greatly benefit your project. Contact us for more details and the best price.

How to make coconut charcoal briquette?

To make coconut shell charcoal briquettes, you will need coconut shells, a charcoal briquette press, and a binder (such as corn starch or cassava flour). Here are the basic steps to making charcoal briquettes:

- Crush the coconut shells into small pieces using a hammer or machine.

- Dry the coconut shells in the sun or in a dehydrator to remove any moisture.

- Grind the dried coconut shells into a fine powder using a grinder.

- Mix the coconut shell powder with a small amount of binder (about 5% of the total weight of the powder) until it forms a dough-like consistency.

- Use the coconut shell briquette machine to shape the mixture into briquettes.

- Dry the briquettes in the sun or in a dehydrator until they are completely dry.

- Your coconut shell charcoal briquettes are now ready to use.

It’s important to note that charcoal making is a dangerous process and should be done with proper safety precautions and professional guidance. Shuliy Machinery is a coconut charcoal briquette plant manufacturer with rich experience and strong capability. If you want to start your coconut charcoal making business, get in touch with us for more details.