Drum Chipper | Best Wood Chipper Machine

| Model | SL-DW218 |

| Knife Quantity | 2/4 |

| Feeding size | 300*680 mm |

| Capacity | 10-15 t/h |

| Raw material dimension | ≤300 mm |

| Wood chip size | 25 mm(adjustable) |

| Main power | 110kw |

| Weight | 8600 kg |

| Feeding inlet conveyor | 6 m |

| Outlet conveyor | 8 m |

| Size | 3105*2300*1650 mm |

Drum chipper is a high-throughput, high-efficiency, high-productivity wood chipper. And it often appears in the preliminary processing of raw materials in various production lines. So it is a wood crushing equipment with a conveyor belt and distribution cabinet. In addition to this, it has a hydraulic feeding system that controls the safe feeding of large pieces of wood. In short, the drum wood chipping machine has the characteristics of wide application, safety, low investment, and fast return. If you have a lot of wood to work with, why not consider it? We sincerely hope to cooperate with you.

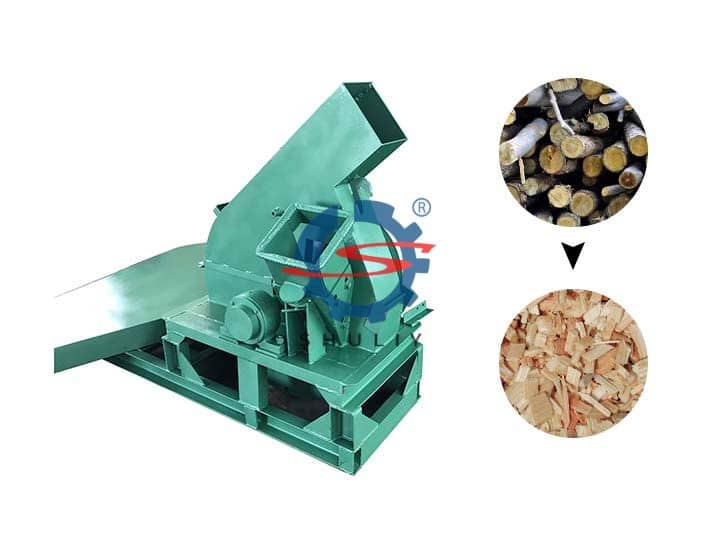

Raw material for drum chipper machine

The raw materials of drum bamboo chipper include wood raw materials and non-wood raw materials. Wood raw materials include logs, bamboo, waste veneer, tree roots, branches, etc. Non-wood raw materials: coconut shell, cotton stalk, reed, straw, etc. Moreover, it can directly process large size raw materials and quickly process regular, neat wood chips.

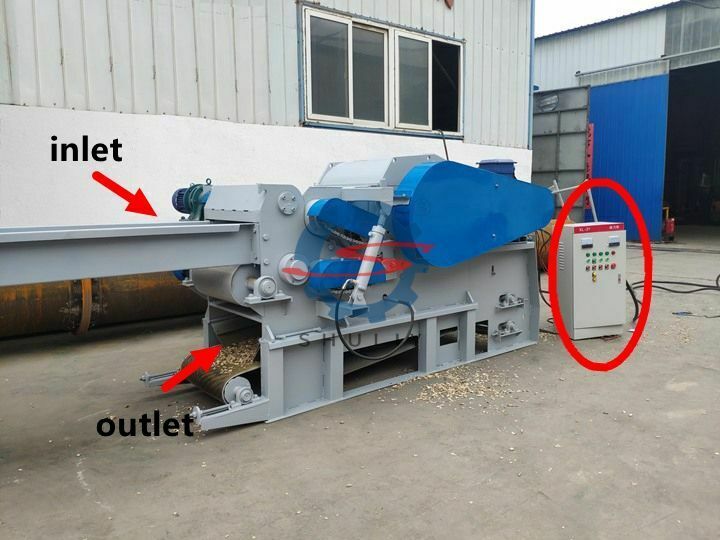

Structure of drum wood chipper

The drum style wood chipper is actually a large wood chipper. What’s more, its structure is more high-end. The machine body is welded with a strong steel plate material to provide strong support for the entire machine. Its main components: machine body, knife roller, screen, upper and lower feeding, hydraulic system, conveying device, accessory cabinet, and other parts.

Safety system of drum wood chipper machine

Shuliy drum tree chipper not only increases the practical performance of the equipment but also takes into account the safety performance of the equipment. The safety device of this drum chips making machine is mainly embodied in the hydraulic system and control cabinet.

Hydraulic system

In this process, the hydraulic system acts as a buffer and can automatically control the feeding port to raise and lower at a constant speed. At the same time, it also protects the large wood chipper and improves the service life of the equipment.

Control cabinet

Drum style wood chipper is a large-scale equipment, its structure is complicated and equipped with 3 motors. The purpose of this is also to reduce the voltage and distribute the power supply reasonably. There are multiple buttons on the control cabinet, which can control the whole machine flexibly. This way is simple, efficient and safe.

Video of drum style chipper

The common size of wood or bamboo treated with it is 5mm. It can also handle raw material to 2-3mm. Welcome to the video. And we have a free consultation service.

Uses of wood chips

- The finished product produced by the coconut shell chipper has a regular shape and uniform thickness. You can choose a wood peeler to process and then chip. These wood chips can be sold directly and burned.

- The drum wood chipper can also be used together with the hammer mill in the charcoal production line and sawdust production line.

- These wood chips can be used for artistic creation in the art industry.

Large wood chipper parameters

| Model | SL-DW218 | SL-DW216 |

| Knife Quantity | 2/4 | 2/4 |

| Feeding size | 300*680 mm | 230*500 mm |

| Capacity | 10-15 t/h | 5-8t/h |

| Raw material dimension | ≤300 mm | ≤230 mm |

| Wood chip size | 25 mm(adjustable) | 25 mm(adjustable) |

| Main power | 110kw | 55kw |

| Weight | 8600 kg | 5600 kg |

| Feeding inlet conveyor | 6 m | 6 m |

| Outlet conveyor | 8 m | 8 m |

| Size | 3105*2300*1650 mm | 2735*2200*1200 mm |

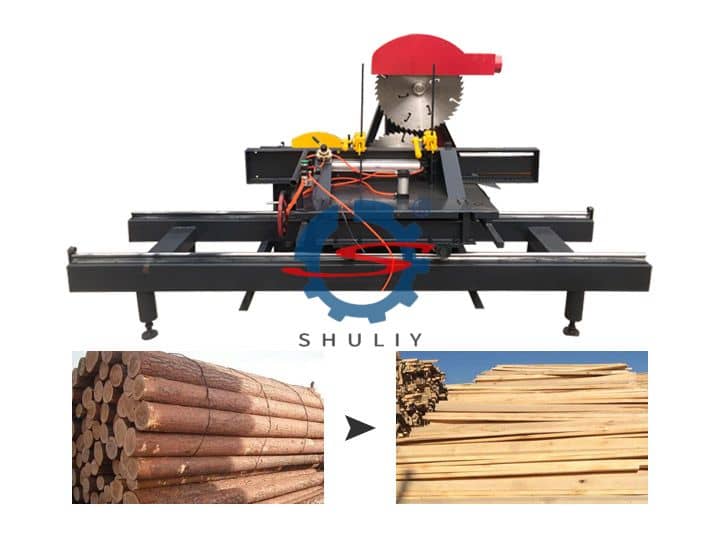

Difference between drum chipper and disc wood chipper

- The feed size of the large wood chip making machine is large. And it can handle wood up to 35cm in diameter.

- The disc wood chipper handles the same amount of raw material as the large bamboo chipper, and the drum chipper consumes less power.

- Ordinary wood chipper is small in size. High-volume drum chippers with conveyor belts are bulky and expensive to ship.

FAQ for drum chips cutting machine

Will you dispatch the engineer to guide installation?

Yes, according to the customer’s requirement, we will dispatch engineers to guide installation and training about the operation of the machines.

How do I know the quality of your machine?

You can send your sample scrap materials to us and we will test the machine for you without charging the fees. And we can send the machine test video to you. We also warmly welcome you to visit our factory to test our machine personally.

Does the drum chipper installation require a foundation?

No, there is conveying and discharging equipment under the machine.

Large wood chipper manufacturer

Shuliy Machinery Equipment Co., Ltd. has been engaged in the wood recycling industry for many years. So we have successfully cooperated with many countries. It laid the foundation for our company’s current good development. The equipment parts we selected meet the international use indicators, and the machinery is fine and durable and has won unanimous praise from customers. Welcome to visit our factory. Contact us now for product price information.