Wood Peeling Machine | Vertical & Trough Log Debarker

| Model | SL-WP320 |

| Power | 7.5+2.2kw |

| Working speed | 10m/min |

| Applicable wood diameter | 50-320mm |

| Machine size | 2450*1400*1700mm |

Wood peeling machine is necessary equipment for some wood recycling industries. It can peel the skin automatically and efficiently, achieving a 95% peeling rate. The log debarker machine produced by Shuliy Machinery manufacturer includes vertical log debarker machines, trough log debarker machines, and horizontal peeling machines. The following are the first two types of wood peeler machines. Welcome to check, if you are interested in our equipment, please contact us in time. And we will provide you with competitive prices.

Type 1:vertical wood peeling machine for sale

Vertical wood peeling machines can process eucalyptus, fruit trees, acacia, alder, pine, locust, beech, and acacia log materials. If the wood is straight and free of knots. The hardwood peeling machine can achieve a peeling rate of more than 98%.

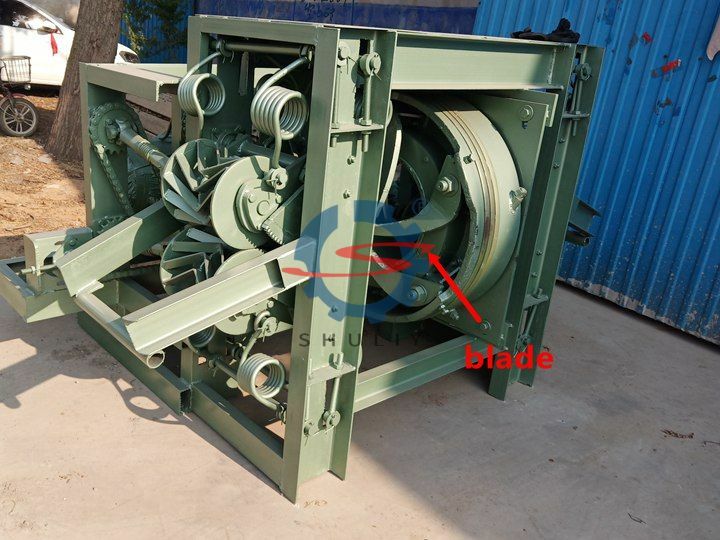

Structure of vertical wood peeling machine

It is a wood peeler machine with a simple structure, which is mainly composed of a pressing roller, a cutter head, and a frame. There are a total of 8 pressure rollers, 4 pressure rollers each at the feed port and the discharge port. The blades are fan-shaped, narrow at the bottom and wide at the top, and 4 or 6 blades can be installed on the cutter head. The number of installed tools can be adjusted appropriately.

Working principle of vertical log debarker

The eucalyptus or pine wood is fed into the feed port manually or by a conveyor belt, and the press roller at the feed port rotates to wind the wood into the machine. The cutter head uses the retractable principle to peel the wood of different diameters. The peeled wood is sent out smoothly by the pressure roller at the discharge port. The pressure rollers at the front and rear of the machine have slow-down springs that can lift and drop the wood.

Video of log debarker

This video will show you the amazing peeling effect of the bark peeler. If you like it, please like and subscribe.

Features of vertical wood peeling machine

1. It can handle wood with a large diameter (5-35cm).

2. Its processing speed is fast, 10m/min.

3. It can peel the skin cleanly and does not damage the wood.

4. It has a compact structure and a small footprint. So it costs low shipping.

Vertical tree peeling machine parameters

| Model | SL-WP320 | SL-WP370 |

| Power | 7.5+2.2kw | 7.5+2.2kw |

| Working speed | 10m/min | 10m/min |

| Applicable wood diameter | 50-320mm | 80-350mm |

| Machine size | 2450*1400*1700mm | 2450*1400*1700mm |

Type 2: trough log debarker

The trough peeling machine can handle more types of wood, including branches, eucalyptus, poplar, fruit trees, pine, locust wood, etc. No matter whether the length of the wood is different, the curvature is different, and the humidity is different, you can peel it on the machine.

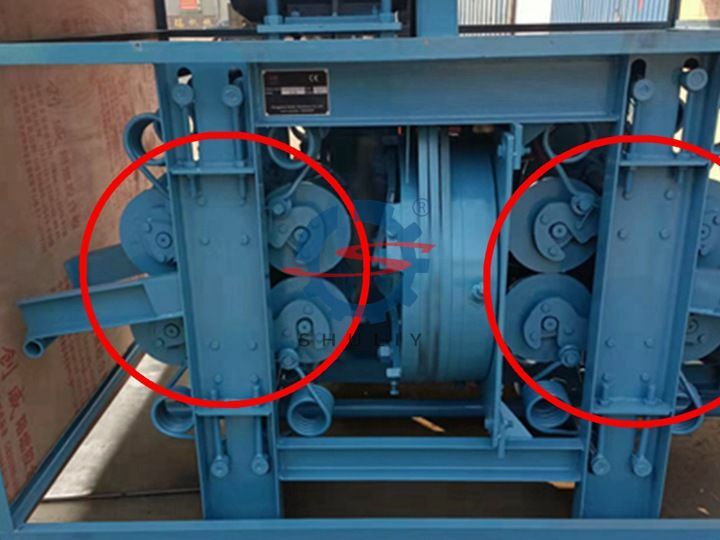

Structure of log peeling machine

The trough debarking machine consists of five parts: debarking roller, feed inlet, debarking outlet, wood outlet, and power transmission device. It adopts roller-type peeling, simple and strong structure, strong rigidity, low failure rate, and long service life.

Working principle of trough log debarker

The trough wood peeling machine utilizes the force generated by the rotor with stepped peeling teeth to make the wood section circulate in the trough. The wood in the trough jumps irregularly. Therefore, the long-term friction and impact between the wood section and the teeth, the wood section and the wood section, and the wood section and the silo trough cause the bark and trunk to be quickly decomposed and peeled, so as to achieve peeling.

Features of trough peeling machine

1. Handling small size wood; the maximum wood diameter does not exceed 30cm.

2. A large amount of wood can be processed at one time; wood of different sizes can be processed at the same time.

3. The roller of the peeling machine is not easy to damage, has no accessories, and has a long service life.

4. Common tank models are 5m, 6m, and 12m; they can be lengthened.

Log peeling machine parameters

| Model | 6m (single roller) | 6m (double rollers) | 9m (double rollers) | 12m double rollers |

| Capacity | 3-7t/h | 7-15t/h | 15-25t/h | 25-30t/h |

| Power | 7.5kw | 7.5+2kw | 7.5+2kw | 7.5+2kw |

| Length | 6300mm | 6300mm | 9000mm | 12600mm |

| Width | 1200mm | 1310mm | 1500mm | 1550mm |

| Height | 1500mm | 1550mm | 1600mm | 1650mm |

Application of peeled wood

Peeled wood can be used in a variety of applications, including decorative and functional uses. Some common uses of peeled wood include:

- Rustic furniture: Peeled wood can be used to create rustic and natural-looking furniture, such as coffee tables, dining tables, and benches.

- Wall coverings: Peeled wood can be used to create a natural and rustic look on walls, either as a decorative feature or as a functional way to hide imperfections.

- Garden edging: Peeled wood can be used to create a natural-looking border around a garden or flower bed.

- Fencing: Peeled wood can be used to create a rustic and natural-looking fence, either as a decorative feature or to mark the boundaries of a property.

- Craft projects: Peeled wood can be used in a variety of craft projects, such as creating rustic signs or decorations.

- Landscaping: Peeled wood can be used in landscaping projects to create natural-looking features, such as retaining walls or raised beds.

Make stakes

Make wooden house building materials

How to choose the right wood peeling machine?

Vertical wood peeling machine has higher requirements for raw materials. If you have a lot of good wood resources (wood characteristics: straight, no stutter, knots, and branches), you can choose a vertical debarking machine. The finished products processed by it can be made into stakes, high-end crafts, or sold directly.

Trough wood peeling machine is suitable for various types of wood, and it is more suitable for thin wood and branches with a diameter of less than 30cm. Raw materials are more widely available. The finished products processed by it are mostly used in wood reprocessing, and manufacturing plants that have higher requirements for recycled products, such as paper mills that require paper quality, advanced charcoal mills, and so on.