Reisschalentrockner | Biomasse-Trocknungsmaschine

| Modell | SL-RD800 |

| Kapazität | 400–600 kg/h |

| Leistung | 4 kW |

| Drehdurchmesser | 0,8 m Durchmesser, Länge 8 m |

Reishülsentro ckner sind wichtige Trocknungsanlagen in der Holzkohleproduktion. Sie können feuchten Sägemehl, feuchte Holzspäne, feuchten Bambus und andere Rohstoffe trocknen. Daher können sie in der Metallurgie, im Bauwesen, in der Chemie, bei der Kohlewäsche, bei Düngemitteln, Erzen, Sand und anderen Bereichen eingesetzt werden. Wir produzieren Trommeltrockner und Luftstromtrockner. Sie zeichnen sich durch Energieeinsparung, guten Trocknungseffekt und einfache Bedienung aus. Sie können uns anrufen oder eine E-Mail senden, und wir werden Ihnen einen wettbewerbsfähigen Preis anbieten.

Welche Arten von Reisschalentrocknern gibt es?

Industrietrockner werden in horizontale Trommeltrockner und vertikale Luftstromtrockner unterteilt. Tatsächlich können beide Trockner Sägemehl, Holzschnitzel, Sand, Dünger, Steine und mehr trocknen. Und der Trocknungseffekt ist ebenfalls gut. Was ist also der Unterschied zwischen ihnen? Wie sollten Sie einen Trockner auswählen? Diese Fragen werden wir als nächstes besprechen.

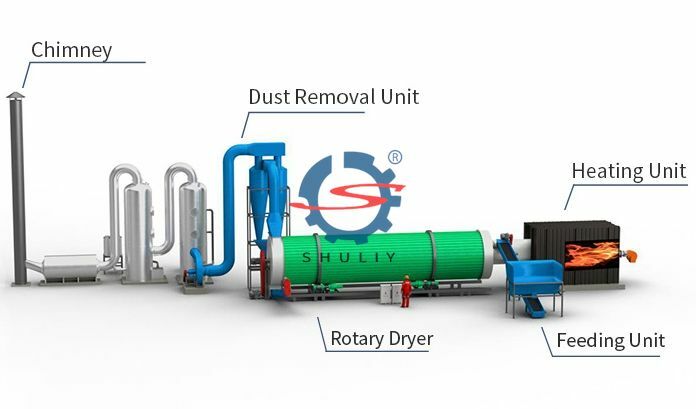

Typ 1: horizontaler Rotationstrockner

Die rotierende Reisschalen-Trocknungsmaschine kann Erz, Ton, Sand, Pulver und andere Materialien trocknen. Wichtig ist, dass seine Trocknungswirkung mehr als 95% erreichen kann. Der Rotationstrockner wird von unseren Kunden am häufigsten bestellt. Mit anderen Worten, es ist das beste Trocknungsgerät, das verkauft wird.

Aufbau der Sägemehltrocknungsmaschine

Seine Hauptmerkmalstruktur ist eine horizontale Rolle. Die Trommeln haben unterschiedliche Durchmesser, um unterschiedliche Leistungen zu erzielen. Im Inneren der Trommel befinden sich viele Hebeplatten. Wenn sich die Trommel dreht, können die Rohstoffe gleichmäßig transportiert werden. Zweitens der Getriebemotor und das Getriebe außerhalb des Zylinders. Die Drehung der Trommel erfolgt über Zahnräder, und die Geschwindigkeitsregelung erfolgt über einen Getriebemotor.

Hauptkörper

Seine charakteristische Hauptstruktur ist eine horizontale Walze. Um unterschiedliche Leistungen zu erzielen, haben die Trommeln unterschiedliche Durchmesser. Im Inneren der Trommel befinden sich viele Hebeplatten.

Elektrosteuerkasten

Der Stromverteilerschrank kann die Temperatur und die Geschwindigkeit des Reduzierers einfach steuern. Daher spielt es auch eine Sicherheitsrolle.

Parameter der Sägemehl-Trocknungsmaschine

| Modell | Kapazität | Leistung | Drehdurchmesser |

| SL-RD800 | 400–600 kg/h | 4 kW | 0,8 m Durchmesser, Länge 8 m |

| SL-RD1000 | 800-1000kg/h | 5,5+5,5 kW | 1m Durchmesser, Länge 10m |

| SL-RD1200 | 1000-1200 kg/h | 7,5+7,5 kW | 1,2 m Durchmesser, Länge 12 m |

| SL-RD1500 | 1500–2000 kg/h | 15+15 kW | 1,5 m Durchmesser, Länge 12 m |

Video einer industriellen Sägemehltrocknungsmaschine

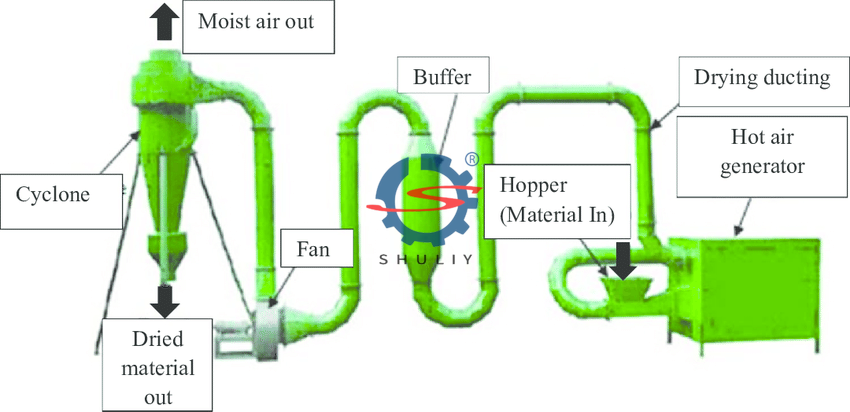

Typ 2: Vertikaler Luftstromtrockner

Der Luftstromtrockner eignet sich besser zum Trocknen leichter Materialien wie Reisschalen, Pulver, Sägemehl, Holzpartikel usw. Seine Entfeuchtungsleistung ist ebenfalls sehr gut. Es muss jedoch die Höhe der Pflanze berechnet werden, sodass die Leistung begrenzt ist.

Aufbau einer Luftstromtrocknungsmaschine

Die Struktur des Reisschalentrockners umfasst hauptsächlich einen Wärmequellenofen, einen Saugzugventilator, eine Trockenkammer, einen Einlass, einen Auslass usw.

Brenner

Es dient als Wärmequelle beim Brennen des Ofens. Darüber hinaus werden seine Rohstoffe nicht benötigt.

Rohr

Der Aufbau und das Aussehen der Trockenkammer der beiden Reisschalentrockner sind unterschiedlich. Es wird ein vertikales Silo verwendet. Daher nimmt es einen kleineren horizontalen Raum ein. Es muss jedoch die Höhe der Pflanze berechnet werden, sodass die Leistung begrenzt ist.

Parameter der Luftstromtrocknermaschine

| Typ | Kapazität | Leistung |

| SL-AD320 | 500-600kg/h | 7,5 kW |

| SL-AD219 | 300-400kg/h | 5,5 kW |

Zugehöriges Zubehör der Reisschalen-Trocknungsmaschine

Beide Arten von Sägemehl-Trocknungsmaschinen basieren auf dem Wärmequellenofen, der die Wärmequelle bereitstellt und dann das Material durch das Saugzuggebläse mit der heißen Luft vermischt. Die Endtemperatur des Produkts liegt bei etwa 50 Grad.

Um die Sicherheit der Bediener zu gewährleisten, empfehlen wir unseren Kunden daher grundsätzlich den Einbau von Kühl- und Staubentfernungsgeräten. Einerseits kann die Luftkühlung das Hochtemperatur-Sägemehl auf 20 Grad abkühlen. Andererseits kann das Staubentfernungsgerät Staub sammeln, um Produktreinheit und Fabrikhygiene sicherzustellen.

Reisschalentrockner zu verkaufen

Wir verkaufen zwei Arten von Reishülsentrocknern: Trommeltrockner und Luftstromtrockner. Und Sie können eine Biomassebrikettmaschine hinter der Maschine platzieren. Wir produzieren Walzendurchmesser von 800 mm, 1000 mm und 1200 mm. Wenn Sie einen größeren Walzendurchmesser benötigen, können wir ihn für Sie anpassen. Die Länge der Trommel ist ebenfalls flexibel. Die Silospezifikationen des Luftstromtrockners sind ebenfalls vielfältig. Kontaktieren Sie uns so schnell wie möglich, wir werden Ihnen die detaillierten Parameter der Reishülsenmaschine zur Verfügung stellen.