เครื่องอบถ่านอัดก้อน | เครื่องอบแห้งด้วยปั๊มความร้อน

| แบบอย่าง | SL-BD 08 |

| ขนาดห้องอบแห้ง | 8ม.*2.3ม.*2.5ม |

| พัดลมหมุนเวียน | 6 ชิ้น |

| พัดลมลดความชื้น | 2 ชิ้น |

| รถเข็น | 8 ชิ้น |

| ถาด | 80 ชิ้น |

เครื่องอบก้อนถ่านหิน เป็นหนึ่งในอุปกรณ์ที่จำเป็นสำหรับสายการผลิตถ่านหิน มันใช้หลักการของการหมุนเวียนอากาศร้อน ดังนั้นจึงสามารถทำงานได้อย่างเสถียร นอกจากนี้ยังสามารถอบวัสดุได้ตลอดเวลาโดยไม่คำนึงถึงสภาพอากาศ ดังนั้น เครื่องอบก้อนถ่านหินจึงเป็นอุปกรณ์ที่ได้รับความนิยมในโรงงานถ่านหินหลายแห่ง โรงงาน Shuliy ขายเครื่องอบถ่านหินสองประเภท: ห้องอบแบบรถเข็นและเครื่องอบสายพานตาข่ายหลายชั้น ซึ่งทั้งหมดเป็นผลิตภัณฑ์ที่มีความประหยัดสูง หากคุณต้องการลงทุนในเครื่องอบ ติดต่อเราวันนี้เพื่อขอราคาที่ดีที่สุด.

วัตถุดิบสำหรับเครื่องอบแห้งถ่านอัดก้อน

ขอบเขตการใช้งานของเครื่องอบแห้งถ่านอัดก้อนนั้นกว้างมาก มันสามารถใช้สำหรับการอบแห้งวัสดุในอุตสาหกรรมการผลิตอาหาร, ยาสมุนไพรจีน, และอุตสาหกรรมถ่านหิน เนื่องจากผลการอบแห้งและแนวคิดการประหยัดพลังงาน การตอบรับจึงดีมาก ดังนั้น โรงงานถ่านหลายแห่งจึงใช้เครื่องอบแห้งถ่านอัดก้อนเพื่อตากผลิตภัณฑ์ถ่าน เช่น ถ่านผงอัดก้อน, ถ่านแบบรังผึ้ง, ถ่านบาร์บีคิว, ถ่านชิชาสี่เหลี่ยม, ถ่านหัวโขกกลม, เป็นต้น.

เครื่องอบถ่านอัดก้อนคืออะไร?

เครื่องอบถ่านอัดก้อนเป็นเครื่องจักรที่ใช้ในการลดความชื้นของถ่านอัดก้อนดิบ โดยปกติจะทำก่อนที่จะบรรจุและจำหน่ายถ่านอัดก้อน เนื่องจากความชื้นอาจทำให้แสงได้ยากและยังส่งเสริมการเจริญเติบโตของเชื้อราและจุลินทรีย์อื่นๆ อีกด้วย เครื่องอบถ่านอัดก้อนมักประกอบด้วยห้องอบแห้ง แหล่งความร้อน และระบบระบายอากาศ โดยทั่วไปแหล่งความร้อนจะเป็นองค์ประกอบความร้อนจากแก๊สหรือไฟฟ้า และระบบระบายอากาศใช้เพื่อหมุนเวียนอากาศผ่านห้องเพื่อส่งเสริมการระเหยของความชื้นจากถ่านอัดก้อน เครื่องอบผ้าบางรุ่นสามารถมีคุณสมบัติในการควบคุมอุณหภูมิและความชื้นได้เช่นกัน

เครื่องอบถ่านมีกี่ประเภท?

เครื่องอบแห้งสองประเภทของเรา: เครื่องอบแห้งกล่องที่มีประสิทธิภาพและเครื่องอบแห้งสายพานตาข่ายแบบต่อเนื่อง หากคุณมีคำถามใดๆ กรุณาทิ้งข้อความไว้.

ประเภทที่ 1: เครื่องอบแห้งถ่านอัดก้อน

เครื่องอบแห้งถ่านอัดก้อนใช้หลักการทำงานของระบบหมุนเวียนอากาศร้อนและระบบลดความชื้น อุณหภูมิในห้องอบแห้งจะถูกตรวจจับโดยอุปกรณ์ควบคุมอุณหภูมิอัจฉริยะ แม้ว่าวัสดุแต่ละชนิดจะมีอุณหภูมิการอบแห้งที่แตกต่างกัน อย่างไรก็ตาม, ลูกค้า สามารถตั้งค่าอุณหภูมิในร่มและเวลาการอบแห้งผ่านตู้จ่ายไฟของเครื่องอบแห้งถ่านอัดก้อนได้เพื่อให้ได้สภาวะการอบแห้งที่ดีที่สุด ดังนั้น เครื่องอบแห้งแบบเตาอบจึงเป็นอุปกรณ์ที่ชาญฉลาดและไม่ยุ่งยาก.

โครงสร้างเครื่องอบแห้งถ่านอัดก้อน

โครงสร้างส่วนใหญ่ประกอบด้วยแหล่งความร้อน พัดลมดูดอากาศ เครื่องลดความชื้น ท่อลมร้อน ตู้ควบคุม รถเข็น ถาด ฯลฯ ดูเหมือนห้อง ลูกค้านำผลิตภัณฑ์สำเร็จรูปใส่รถเข็นแล้วดันเข้าไปในห้องอบแห้ง นอกจากนี้ยังสามารถปรับแต่งขนาดได้ โดยทั่วไปขนาดของมันจะสัมพันธ์กับจำนวนรถเข็น รถเข็นแต่ละคันมี 10 ชั้น

ปั๊มความร้อนพลังงานอากาศ

รูปลักษณ์และหลักการทำงานคล้ายกับเครื่องปรับอากาศแบบแขวน ดังนั้นจึงประหยัดพลังงานและเป็นมิตรต่อสิ่งแวดล้อม

ตู้ควบคุม กล่อง

ลูกค้าสามารถตั้งอุณหภูมิและเวลาได้ การควบคุมอัตโนมัติ: การใช้ระบบควบคุมแบบรวม อินเทอร์เฟซระหว่างคนกับเครื่องจักร และการควบคุมอัตโนมัติโดยไม่มีบุคลากรปฏิบัติหน้าที่

พัดลมเหนี่ยวนำ

สามารถสูบลมร้อนเข้าสู่ห้องอบแห้งได้อย่างต่อเนื่อง นอกจากนี้ยังมีบทบาทในการไหลเวียนของก๊าซอีกด้วย

พารามิเตอร์ของเครื่องอบแห้งถ่านอัดก้อน

| แบบอย่าง | SL-BD 08 | SL-BD 010 |

| ขนาดห้องอบแห้ง | 8ม.*2.3ม.*2.5ม | 10ม.*2.3ม.*2.5ม |

| พัดลมหมุนเวียน | 6 ชิ้น | 6 ชิ้น |

| พัดลมลดความชื้น | 2 ชิ้น | 2 ชิ้น |

| รถเข็น | 8 ชิ้น | 10 ชิ้น |

| ถาด | 80 ชิ้น | 100 ชิ้น |

วิดีโอโรงงานเครื่องเป่ากล่องนัดจริง

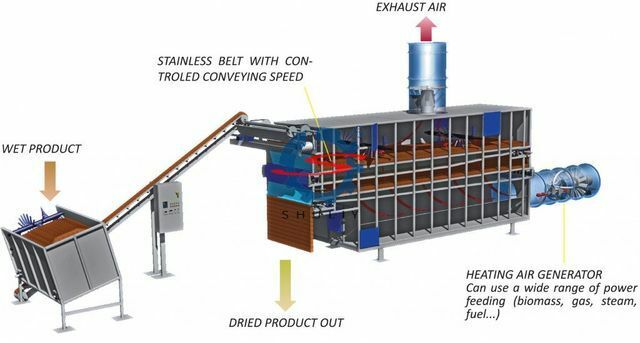

ประเภทที่ 2: เครื่องอบแห้งแบบสายพานตาข่ายหลายชั้น

ผู้ปฏิบัติงานจำเป็นต้องใส่วัตถุดิบ (เช่น ถ่านอัดแท่ง ถ่านบาร์บีคิว สมุนไพร ฯลฯ) ลงในช่องป้อนอาหาร สายพานตาข่ายที่เคลื่อนย้ายได้จะขับถ่านหินให้กระจายออกไปและเข้าสู่ห้องอบแห้งเพื่อทำให้แห้ง ถ่านหินเคลื่อนที่ผ่านเครื่องอบแห้งแบบสายพานตาข่าย และอากาศร้อนจะร้อนสม่ำเสมอและทำให้วัตถุดิบแห้ง นอกจากนี้ ลูกค้าสามารถปรับปริมาณความชื้นของวัตถุดิบขั้นสุดท้ายได้โดยการปรับความเร็วในการเคลื่อนที่ของเครื่องทำแห้งแบบสายพานตาข่าย

โครงสร้างเครื่องอบแห้งแบบสายพานตาข่าย

โครงสร้างประกอบด้วยช่องป้อน สายพานลำเลียงสแตนเลส เครื่องกระจาย ห้องอบแห้ง แหล่งความร้อน ช่องระบาย พัดลมดูดอากาศ ฯลฯ

สายพานตาข่ายสแตนเลส

วัสดุไม่เสียหายง่ายและมีอายุการใช้งานยาวนาน และแต่ละชั้นของสายพานตาข่ายมีมอเตอร์ปรับความเร็วได้ ด้วยวิธีนี้ สายพานลำเลียงตาข่ายสายพานลำเลียง จึงสามารถเคลื่อนย้ายได้เท่าๆ กัน

ทางเข้า

ไม่เพียงแต่สามารถเลี้ยงได้อย่างต่อเนื่องเท่านั้น และเครื่องอบแห้งแบบสายพานตาข่ายแบบต่อเนื่องสามารถกระจายวัสดุได้โดยอัตโนมัติ

พารามิเตอร์ของเครื่องอบแห้งแบบสายพานตาข่ายแบบต่อเนื่อง

| แบบอย่าง | LTWD-6 | LTWD-8 | LTWD-10 | LTWD-12 | LTWD-16 | LTWD-20 | LTWD-24 | LTWD-30 |

| ความกว้างของสายพาน | 600มม | 800มม | 1,000มม | 1200มม | 1600มม | 2000มม | 2400มม | 3000มม |

| ความยาวของส่วนการอบแห้ง | 6-12 | 6-12 | 6-16 | 8-16 | 8-22 | 10-26 | 12-30 | 12-40 |

| ความยาวของส่วนการให้อาหาร | 1 | 1 | 1 | 1 | 1 | 1.5 | 1.5 | 2 |

| ความยาวของส่วนการส่งสัญญาณ | 1 | 1 | 1 | 1 | 1 | 1.5 | 1.5 | 2 |

| พื้นที่อบแห้ง | 3.6-36 ตร.ม | 4.8-48 ตร.ม | 6-80 ตร.ม | 7.2-96 ตร.ม | 12.8-105.6 ตร.ม | 20-260 ตร.ม | 28.8-360 ตร.ม |

ขายถ่านหิน เครื่องอบแห้ง

เครื่องอบแห้งถ่านอัดก้อนมักปรากฏใน สายการผลิตถ่านหัวโขก, สายการผลิตถ่านรูปทรง, และสายการผลิตถ่านหิน นอกจากนี้ ถ่านอัดก้อนที่อบแห้งแล้วสามารถบรรจุได้โดยตรงด้วย เครื่องบรรจุถ่านอัดก้อน. เราขายห้องอบแห้งถ่านขนาดเล็กและเครื่องอบแห้งสายพานตาข่าย สเปคของพวกเขายืดหยุ่นและปรับแต่งได้ ดังนั้น คุณสามารถบอกความต้องการเฉพาะของคุณและเราจะให้พารามิเตอร์เฉพาะของเครื่อง.

บทสรุป

เครื่องอบก้อนถ่านหินเป็นส่วนสำคัญของทั้ง สายการผลิตถ่านหิน โดยการลดความชื้นของก้อนถ่าน ทำให้เครื่องเหล่านี้ปรับปรุงคุณสมบัติการจุดติดและการเผาไหม้ ป้องกันการเจริญเติบโตของเชื้อราและจุลินทรีย์ และเพิ่มอายุการเก็บรักษา ขณะที่ความนิยมของก้อนถ่านหินยังคงเติบโต การวิจัยและพัฒนาในด้านนี้น่าจะยังคงปรับปรุงประสิทธิภาพและความมีประสิทธิผลของเครื่องอบก้อนถ่านหิน เป็นสิ่งสำคัญสำหรับผู้ซื้อที่จะต้องพิจารณาปัจจัยต่างๆ เมื่อเลือกเครื่องอบ และรักษาความสะอาดเป็นประจำเพื่อให้แน่ใจว่ามันทำงานได้อย่างดีที่สุด หากมีอะไร กรุณาติดต่อผู้เชี่ยวชาญ Shuliy เพื่อขอคำแนะนำอย่างมืออาชีพ.