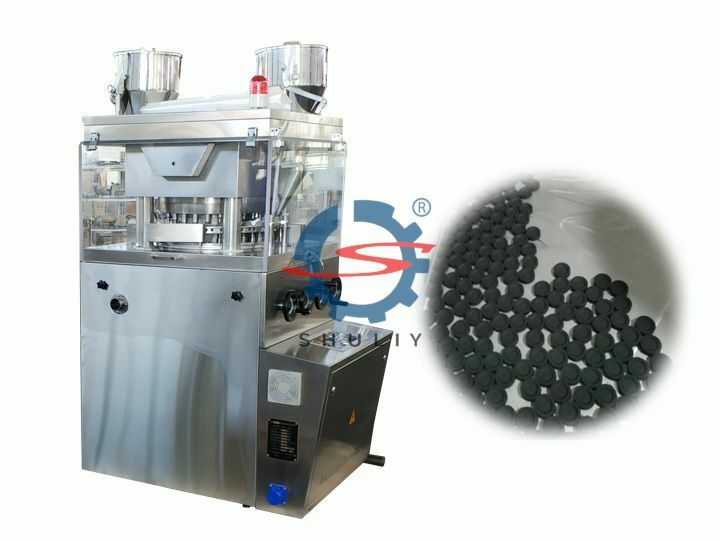

เครื่องกดถ่านหินรังผึ้ง | เครื่องอัดก้อนถ่านหิน

| แบบอย่าง | SL-HC120 |

| พลัง | 5.5kw |

| เส้นผ่านศูนย์กลางสูงสุดของถ่าน | 120มม |

เครื่องอัดถ่านหินรูปแบบรังผึ้ง เป็นอุปกรณ์พิเศษสำหรับการผลิตถ่านก้อนที่มีความหนาแน่นสูง รูปทรงกระบอกที่มีรูพรุน เครื่องอัดถ่านรังผึ้งนี้ยังสามารถผลิตแท่งถ่านหินแบบกลวงและ แท่งถ่าน วัสดุที่ใช้หลักๆ คือ ถ่านหินที่ถูกบดละเอียดและผงคาร์บอน นอกจากนี้ยังมีวัสดุอื่นๆ เช่น หญ้าอัลฟัลฟา และหญ้าทิมอธี ใน addition, เครื่องอัดถ่านก้อนนั้นใช้งานง่าย มีประสิทธิภาพสูง และดูแลรักษาง่าย ดังนั้นจึงได้รับความนิยมจากลูกค้าส่วนใหญ่ ติดต่อเราตอนนี้เพื่อเริ่มสร้างความสัมพันธ์ทางธุรกิจ เราจะเสนอราคาที่ดีกว่าให้คุณ

หลักการทำงานของเครื่องกดถ่านหินแบบรังผึ้ง

เครื่องอัดถ่านหินรูปแบบรังผึ้ง เป็นเครื่องทำถ่านที่มีประเภทการอัดที่ใช้งานง่ายที่สุด และมีความจุไซโลขนาดใหญ่ ดังนั้นผู้ผลิตถ่านบาร์บีคิวบางรายจะมีแนวโน้มที่จะซื้อตู้ทำถ่านรังผึ้งสำหรับ การผลิตถ่านก้อน เครื่องนี้ใช้พลังงานจากมอเตอร์ไฟฟ้าหรือเครื่องยนต์ดีเซล จากนั้นผงถ่านหรือผงถ่านหินจะตกลงบนแผ่นแม่พิมพ์ผ่านทางเข้าป้อนและทำการอัดเป็นถ่านก้อนด้วยแม่พิมพ์

โครงสร้างของเครื่องอัดถ่านหินแบบรังผึ้ง

โครงสร้างของเครื่องอัดก้อนรังผึ้งส่วนใหญ่ประกอบด้วยช่องป้อนอาหาร เข็มเจาะ มีดโกน แม่พิมพ์ และสายพานลำเลียง ด้านล่างนี้ ผมจะแนะนำฟังก์ชันและคุณประโยชน์ของช่องป้อนอาหาร เข็มเจาะ และเครื่องขูดโดยละเอียด

ทางเข้า

ถังป้อนอาหารของเครื่องอัดก้อนแบบรังผึ้งติดตั้งแท่งกวนแบบหมุนได้ หน้าที่ของมันคือป้องกันไม่ให้วัตถุดิบที่หลวมปิดกั้นช่องป้อนอาหารและป้อนอย่างเท่าเทียมกัน

เข็มเจาะ

การหล่นของแผ่นแม่พิมพ์ถ่านหินจะกดถ่านหินที่บดไว้ล่วงหน้า จากนั้นใช้หมัดแรงดันสูงอย่างรวดเร็วกับถ่านหินที่บดแล้ว ในความเป็นจริง briquettes ที่ขึ้นรูปแล้วถูกกดสองครั้ง ดังนั้นความหนาแน่นและความแข็งของผลิตภัณฑ์สำเร็จรูปจึงเหมาะสมที่สุดแล้ว

ที่ขูด

ใช้เพื่อทำความสะอาดผงคาร์บอนที่กระจัดกระจายในระหว่างกระบวนการผลิต แขนโยกสามารถควบคุมการทำงานได้โดยอัตโนมัติโดยไม่ต้องดำเนินการด้วยตนเอง

วิดีโอของเครื่องทำอิฐก้อนรังผึ้ง

ข้อมูลจำเพาะของเครื่องอัดก้อนถ่านหิน

ต่อไปนี้เป็นพารามิเตอร์ของมอเตอร์และแม่พิมพ์สำหรับการอัดถ่านหินทั่วไปหลายแบบ โรงงานของเราสามารถให้บริการปรับแต่งแม่พิมพ์ได้ คุณจึงไม่ต้องกังวลกับปัญหาเชื้อรา นอกจากนี้เครื่องอัดถ่านหินแบบรังผึ้งยังมาพร้อมกับสายพานลำเลียงยาว 2 เมตร ความยาวของมันสามารถปรับแต่งได้ตามความต้องการของลูกค้า

| แบบอย่าง | พลัง | เส้นผ่านศูนย์กลางสูงสุดของถ่าน |

| SL-HC120 | 5.5kw | 120มม |

| SL-HC140 | 7.5kw | 140มม |

| SL-HC160 | 11กิโลวัตต์ | 160มม |

| SL-HC220 | 11กิโลวัตต์ | 220มม |

แม่พิมพ์ของเครื่องอัดก้อนถ่านหินดีเซล

ภายใต้สถานการณ์ปกติ ความสูงสูงสุดของ briquettes ที่เครื่องอัดผงถ่านหินบดนี้สามารถผลิตได้คือ 13 ซม. ความสูงทั่วไปคือ 8-10 ซม. นอกจากนี้ยังสามารถสร้างรูปทรงต่างๆ ของคอมแพคได้โดยการเปลี่ยนแม่พิมพ์ โดยรูปทรงที่ได้รับความนิยมมากที่สุด ได้แก่ รูปทรงหกเหลี่ยม ทรงกลม ทรงสี่เหลี่ยม ทรงรังผึ้ง และอื่นๆ

คุณสมบัติของเครื่องกดถ่านหินรังผึ้ง

- โครงสร้างที่เรียบง่ายและการทำงานที่สะดวก

- ไม่มีอุปกรณ์เสริม อายุการใช้งานยาวนาน.

- ด้วยการบีบอัดล่วงหน้า ผลิตภัณฑ์สำเร็จรูปจะมีความหนาแน่นสูง

- โรงงานของเราให้บริการที่กำหนดเองสำหรับเครื่องกดอัดก้อนถ่านหินรังผึ้ง ตัวอย่างเช่น แม่พิมพ์ ขนาดของพอร์ตทางเข้า ขนาดของพอร์ตทางออก ฯลฯ

- มีสองโหมดพลังงาน: มอเตอร์และดีเซล

ขายเครื่องทำก้อนถ่านหินดีเซล

Zhengzhou Shuliy Machinery Equipment Manufacturer คือผู้ให้เครื่องทำถ่านชื่อดังในประเทศจีน เราให้เครื่องอัดแท่งถ่านไฟฟ้าและเครื่องอัดแท่งถ่านดีเซลเพื่อขาย น moreover we have now developed a double-feed briquette machine...