Kömür Tozu Briket Makinası | Kömür Pres Makinesi Üreticisi

| Modeli | SL-CB140 |

| Uzunluk*Genişlik*Yükseklik (mm) | 1950*1260*1080 |

| Ağırlık (kg) | 650 |

| Motorlu (kw) | 11 |

| Çıkış (t/saat) | 1-2 |

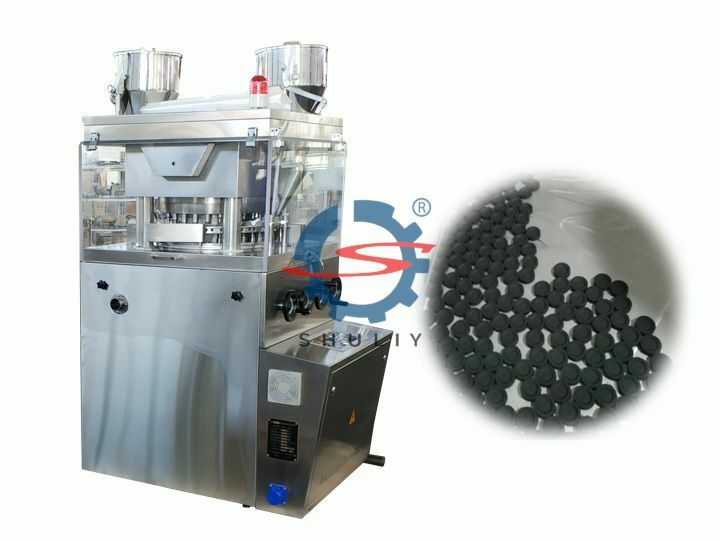

Charcoal powder briquette machine is a kind of equipment that mainly uses charcoal powder and coal powder as raw materials to produce barbecue charcoal and square hookah charcoal. Charcoal dust briquetting can be hollow and non-hollow. And their cross-sectional profile can be square, hexagonal, circular, and the like. More importantly, briquette is smokeless, has a long burning time, and has large market demand. Therefore, the charcoal briquetting machine is cost-effective charcoal equipment. Welcome to contact us, we will give you a competitive price.

Kömür Tozu Briket Makinasının Çalışma Prensibi

Kömür makinesi, toz kömürü farklı şekillerde kömür blokları haline getiren bir makinedir. Çalışma prensibi, motorun gücü V kayışı üzerinden şanzımana iletmesidir. Şanzıman çıkış mili daha sonra yüzer bir kaplin aracılığıyla gücü kardan miline iletir. Son olarak, pervane şaftındaki pervane, ham maddeyi şekillendirme kalıbının içinden dışarı itebilir.

Kömür Tozu Briketleme Makinesi Hammaddeleri

The source of its raw charcoal powder is that various charcoal can be crushed by hammer mill. For example, coconut shell charcoal, log charcoal, sawdust briquette carbon, palm shell charcoal, rice husk charcoal, peanut shell charcoal, etc. And other materials: Alfalfa and Timothy grass. It is worth noting that the crushed carbon powder needs to be fully mixed with a certain proportion of water and binder with a wheel mill before use. Because, it can make the carbon powder more viscous, shape better, and the finished product quality higher.

Kömür Tozu Briket Makinasının Yapısı

Kömür Tozu Briket Makinesi esas olarak ana şaft, vidalı itici, kalıp, dişli motor ve diğer parçaları içerir. Genel tasarımı nedeniyle yapı kompakttır. Bu nedenle kapladığı alan küçüktür. Üstelik iticisi üç parçadan oluşuyor. Kömür briket makinesinin iticisi arızalandığında müşterinin yalnızca kafasını değiştirmesi gerekir.

Kömür Briket Makinesi Aksesuarları

Kalıp

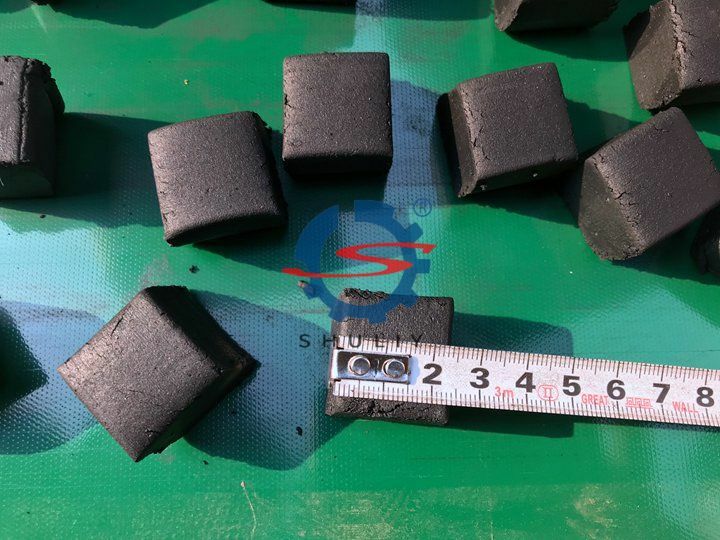

Kömür tozu kalıplama makinesinin çeşitli kalıpları vardır. Bu nedenle çeşitli şekillerde barbekü kömürü üretebilmektedir. Örneğin altıgen, sekizgen, kare, daire.

Propeller shaft

Fabrikamız makinaların aksesuarlarını kendimiz üretmektedir. pervaneler gibi. Çünkü aksesuar yapmak için iyi metal malzemeler seçiyoruz. Bu nedenle kullanımı kolay zarar görmez ve uzun ömürlüdür. Üstelik satış sonrasında da müşterilerimize her an uygun aksesuarları sunabiliyoruz.

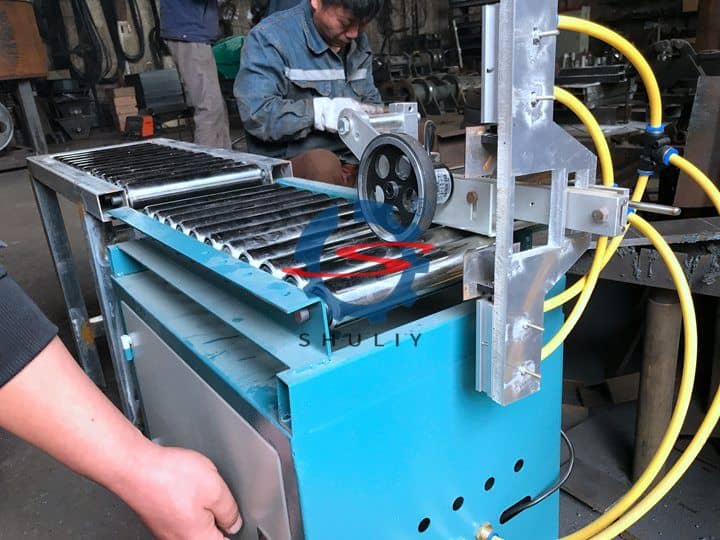

Kömür Pres Makinesi için Kesme Ekipmanı

The formed carbon block needs to be cut into different sizes. Therefore, it is necessary to use a cutter tool. We can provide three kinds of cutters: automatic cutter, meter cutter, and hob. Both the first and second mentioned cutters require an air compressor. Adjust the strength of the cutter by controlling the air pressure.

Kömür Briket için Otomatik Kesici

Çalışma prensibi, kızılötesi sensör probu ile kömür briket makinesinin boşaltma portu arasındaki mesafeyi aynı boyutta kesecek şekilde ayarlamaktır.

Briketler için CNC Kesici

CNC sistemidir. Böylece hassas bir kesme uzunluğu ayarlayabilir. Uzunluğu bile ondalık noktayla ayarlayın. Avantajları: akıllı, doğru ve kompakt. Bu kesiciyi seçmenizi şiddetle tavsiye ederiz.

Küp Kömür Kesimi

Prensibi özellikle basittir. Yani, kesici merdane üzerine birden fazla dairesel kesici kafa takılıdır. Kesici kafa mesafesi ayarlanabilir. Bu kesici nargile kömürü üretimi için çok uygundur. Bu nedenle Endonezya ve Arap ülkelerinden müşteriler tarafından sıklıkla satın alınmaktadır.

Kömür Pres Makinasının Teknik Parametreleri

Müşteriler için konveyör bantlarını yapılandırabiliriz. Ve konveyör bandının uzunluğu ve genişliği müşteri ihtiyaçlarına göre özelleştirilebilir.

| Modeli | Uzunluk*Genişlik*Yükseklik (mm) | Ağırlık (kg) | Motorlu (kw) | Çıkış (t/saat) |

| SL-CB 140 | 1950*1260*1080 | 650 | 11 | 1-2 |

| SL-CB 160 | 2150*1260*1080 | 720 | 15 | 1-2 |

| SL-CB 180 | 2320*1600*1150 | 1260 | 22 | 2-4 |

Kömür Tozu Briket Üretim Hattı Videosu

Satılık Kömür Briket Makinesi

Our company is a manufacturer of coal presses. We produce different types of coal press machine. The characteristics of our charcoal powder briquette machine are simple operation, long service life and multi-function. We provide customers with a variety of production molds. In addition, we also sell pulverized coal mixers, honeycomb coal machines, and so on. So contact us now to start your business. We are glad to serve you.

Barbekü Kömürü için Kömür Tozu Briket Makinesi

Coal briquettes extruder machine can make barbecue charcoal. But the charcoal block it just made cannot be used directly. It needs to be dried naturally or in a dryer. The dried coal briquettes are generally handled by a charcoal briquetting packaging machine for sale. In fact, this machine is also very suitable for making hookah charcoal, which is more economical.