Shisha 숯 생산 라인

| 상표 | 슈리 |

| 원료 | 통나무, 대나무, 왕겨, 코코넛 껍질, 톱밥 등 |

| 메모 | 맞춤 서비스 가능 |

Shisha charcoal production line 은 다양한 원재료를 사용하는 차 charcoal briquette 생산 시스템입니다. 예를 들어, 통 charcoal, 과일 charcoal, 쌀 겨, 코코넛 껍질 charcoal, 대나무 charcoal, charcoal powder 등. 일반 샤샤 라브 카르본의 생산 공정은 주로 탄화, 분쇄, 교반, 압입, 건조 및 포장을 포함합니다. 최종적으로 얻어지는 훅ah charcoal 제품은 높은 강도, 낮은 재 내용, 긴 연소 시간을 특징으로 해야 합니다. 훅ah charcoal 압연 생산 라인은 차charcoal 생산에 종사하는 많은 고객들에게 유망한 사업입니다. 따라서 수익률이 높은 프로젝트입니다. 문의 환영하며, 할인 혜택을 드리겠습니다.

물 담뱃대 숯 생산 라인의 원료

모든 종류의 숯을 물담배 숯의 원료로 사용할 수 있습니다. 그러나 일반 고객은 고품질 물담배 숯을 만들기 위해 다음과 같은 원료를 선택합니다. 예를 들어 코코넛 껍질 숯, 왕겨 숯, 야자 껍질 숯, 단단한 숯, 과일 숯, 대나무 숯 등이 있습니다. 이 나무 숯은 탄소 함량이 높고 색상이 좋으며 불순물이 적은 특성을 가지고 있습니다. 그래서 시샤 숯으로 만든 연탄도 시장에서 큰 인기를 끌고 있다.

물담배 숯 생산 라인 공정

샤샤 charcoal 생산 라인의 완전한 생산 공정은 다음 단계로 구성됩니다: 탄화→분쇄→혼합→압입→건조→포장.

일반적으로 훅ah charcoal의 생산 공정은 탄화로, 해머밀, charcoal grinder mixer, 훅ah charcoal tablet machine, dryer, 포장기 및 기타 장비를 포함합니다.

주요 부분 시샤 숯 만들기 라인

시샤 숯 생산 라인은 물담배 숯 또는 나르길레 숯으로도 알려진 시샤 숯을 제조하는 데 사용되는 일련의 기계 및 장비입니다. 시샤 숯은 향이 나는 담배를 피우는 데 사용되는 수도관인 시샤 파이프에 사용하도록 특별히 고안된 일종의 숯입니다. 물담배 숯 제조 라인의 주요 부분은 다음과 같습니다.

연속탄화로(탄화)

원재료의 범주가 넓습니다. 보통 소형의 가볍고 재료입니다. 예를 들어 톱밥, 쌀겨, 목재 칩 등. 따라서 목재 펠렛을 직접 탄화시킬 수 있습니다. 왜냐하면 훅ah charcoal은 원재료의 미세도에 대해 높은 요구를 하기 때문입니다. 따라서 레이몬드 밀 사용을 권장합니다. 이로써 카본 파우더를 80메시로 분쇄할 수 있습니다.

해머밀(분쇄)

원료가 유실목, 견목 등인 경우 탄화를 위해 수직형 탄화로를 사용해야 합니다. 그런 다음 숯 분쇄기를 사용하여 숯을 1mm의 미세한 숯 가루로 분쇄합니다.

숯 분쇄기 믹서(혼합)

그 기능은 숯가루와 바인더를 완전히 혼합하는 것입니다. 재료가 바닥에서 배출될 수 있어 매우 편리합니다. 믹싱 탱크와 함께 사용하여 미리 접착 비율을 준비할 수도 있습니다.

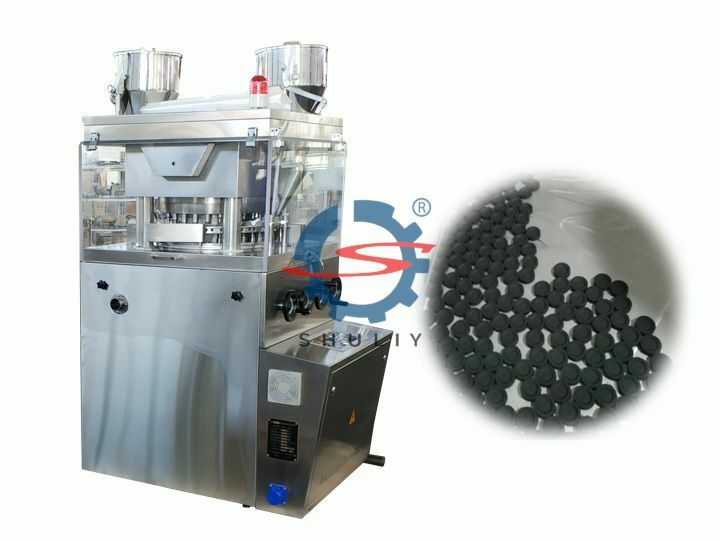

시샤 숯 타정기(정제)

선택할 수 있는 세 가지 유형의 시샤 숯 정제 기계가 있습니다. 그들은 기계식 물담뱃대 숯 정제 프레스, 유압식 물담뱃대 숯 정제 프레스 및 스테인레스 스틸 물담뱃대 숯 정제 기계입니다. 출력 크기에 따라 선택할 수 있습니다.

물담뱃대 연탄 포장 기계

원형 훅ah charcoal의 경우 베개 포장기를 선택하는 것을 권장합니다. 이에는 이송 구역과 원료 취급 구역이 포함됩니다. 충분한 인력이 있다면 포장 기계만 선택해도 됩니다. 포장 백의 경우 패턴, 문자 등 정보를 디자인하는 제조사를 제공할 수 있습니다. 직사각형 훅ah charcoal의 경우 양적 포장기를 사용하는 것을 권장합니다.

물담배 숯 프로젝트 라인 호퍼

시샤 숯 생산 라인에는 일반적으로 재료를 저장하는 데 주로 사용되는 다양한 기능성 호퍼가 장착되어 있습니다.

Charcoal powder storage bin

일반적으로 숯가루 혼합기 앞에 배치되어 준비된 재료를 보관하고 생산과정을 완충하는 역할을 합니다.

Charcoal dust distributor

일반적으로 물담배 숯 압착기 앞에 배치되어 처리된 숯 가루를 저장합니다. 게다가 다양한 스펙을 가지고 있습니다. 따라서 여러 개의 물담배 숯 정제 프레스의 작업 요구 사항을 충족할 수 있습니다.

Shuliy 시샤 숯 제조기의 장점

- 우리는 10년 이상의 경험을 가진 물담배 숯 프로젝트 라인 제조업체입니다.

- 우리는 모든 종류의 전문 물담뱃대 숯 생산 장비를 제조합니다. 탄화로, 숯 분쇄기, 레이몬드 밀, 물 담뱃대 숯 성형 기계 등

- 우리는 고객의 특정 원자재 및 생산량 요구 사항에 따라 다양한 생산 솔루션을 제공합니다.

- 우리 공장은 언제든지 고객에게 원래의 예비 부품을 제공할 수 있습니다.

- 우리는 고객에게 무료 설치 및 시운전 서비스를 제공합니다.

인도네시아 시샤 숯 생산 라인 고객의 피드백 비디오

물담배 숯 정제 장비를 선택하는 방법은 무엇입니까?

원료가 숯가루인 경우 숯가루 믹서를 직접 선택하여 물담배 숯 생산용 숯가루를 처리할 수 있습니다.

경험이 풍부한 물담배 숯 제조업체이고 대량, 고품질 생산이 필요한 경우 스테인리스 스틸 허브 숯 기계 또는 회전식 정제 프레스를 선택하는 것이 좋습니다. 두 개의 시샤 숯 타블렛 프레스가 CNC 기술을 사용하기 때문입니다. 따라서 고도로 자동화된 생산을 실현할 수 있는 두 가지 유형의 장비입니다. 또한 손상될 가능성이 적고 조정도 쉽습니다.

고품질의 물담배 숯을 만드는 방법?

고품질의 시샤숯을 만들고 싶다면 먼저 고품질의 시샤숯의 특성을 이해해야 합니다. 조사에 따르면, 아랍인들의 눈에 보이는 고품질의 숯 성형체는 다음과 같은 특징을 가지고 있습니다.

1. 물담배 숯 조각은 1분 이내에 점화됩니다.

2. 물담배 숯 한 조각은 최소 1시간 동안 태울 수 있습니다.

3. 탄 물담배 숯이 덩어리져 있습니다.

4. 연소시 연기가 발생하지 않습니다.

5. 연소 시 특유의 냄새가 나지 않습니다.

위의 조건을 충족시키기 위해서는 먼저 좋은 원료를 선택해야 합니다. 예를 들어, 코코넛 껍질 숯. 둘째, 생산과정에서 접착제의 선택과 비율도 매우 중요하다. 마지막으로, 숯 연탄 기계의 톤수가 높을수록 좋습니다.