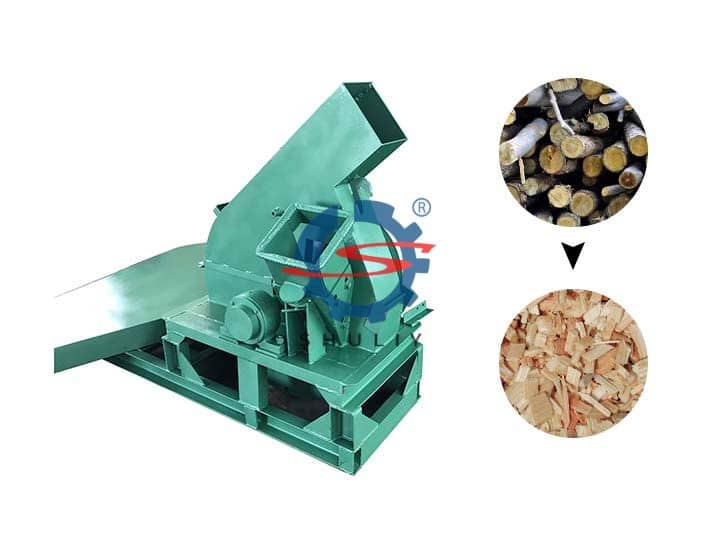

ログチッパー |木材チップ切断機

| モデル | SL-420 |

| 容量 | 500KG/H |

| 入力サイズ | 150*150MM |

| 出口サイズ | 2~5cm |

| ディーゼルパワー | 15馬力 |

ログチッパーは、木材生産ラインおよび木材再加工プロセスにおける重要な機械です。その機能は、回転ナイフと固定ナイフを使用して、木材、枝、竹を同じ厚さとサイズの断片に切断することです。これらの木材チップは製紙、燃料燃焼などに使用され、需要が高いです。当社は、高品質で省エネ、使いやすい木材チップ製造機をお客様に提供しています。お問い合わせください。お手頃な価格でご提供いたします。

ログチッパーの動作原理

木材スライシングは、木材の再加工または破砕において重要なステップです。丸太、竹、木板などの原材料を投入口に入れます。次に、モーターがベルトを駆動してカッターヘッドを回転させ、チップ化します。供給と排出はほぼ同期しています。最終的に、均一な厚さと規則的な形状の木材チップが得られます。

木材チッパーマシンの原料

市販の木材チッパーは、松、雑木、ポプラ、モミ、生竹、PPRパイプなどを処理できます。選択された原材料はできるだけ規則的である必要があり、木材チップの製造効果がより優れています。

ログチッパーの構造

ウッドチッパーは主にカッターヘッド、プーリー、スピンドルフレーム、供給ポート、カバー、電気制御システムで構成されています。全体の構造がコンパクトで省スペースです。ただし、出力の向上、省エネ、安全で便利な操作などの特性には影響しません。

調整可能なブレード

木材チップの厚さは、ブレードの角度を調整することで変更できます。さらに、各ブレードには少なくとも3本のネジで固定されており、緩みにくいです。ブレードが摩耗した場合は、シャープナーで簡単に固定できます。

カッターディスク

ウッドチッパーブレードディスクは複数のブレードを保持できます。また、ログチッパーのモデルが異なれば、カッターヘッドの直径も異なります。刃の枚数も違います。

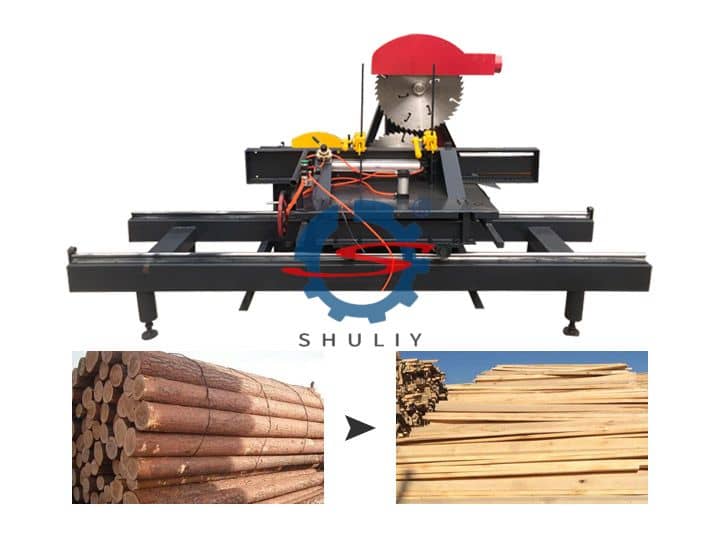

販売されている最高の商用木材チッパー機械

電動ウッドチッパーとディーゼルウッドチッパーを販売しております。お客様の作業環境は多様であるため、生産要件も異なります。そのため、私たちは数多くの特殊木材チッパーを改良してきました。車輪付き、出口下部と上部出口、傾斜入口など。

電動木材チッパーのパラメータ

| モデル | 容量 | 入力サイズ | 出口サイズ | 電力 |

| SL-420 | 500KG/H | 150*150MM | 2~5cm | 11kw |

| SL-600 | 1500KG/H | 180*150MM | 2~5cm | 18.5kw |

| SL-800 | 3000KG/H | 200*200MM | 2~5cm | 30kw |

| SL-950 | 4000KG/H | 230*250MM | 2~5cm | 37kw |

| SL-1200 | 5000KG/H | 330*300MM | 2~5cm | 55kw |

| SL-1400 | 7000-8000KG/H | 400*400MM | 2~5cm | 90kw |

ディーゼル木材チッパーのパラメータ

| モデル | 容量 | 入力サイズ | 出口サイズ | ディーゼルパワー |

| SL-420 | 500KG/H | 150*150MM | 2~5cm | 15馬力 |

| SL-600 | 1500KG/H | 180*150MM | 2~5cm | 22馬力 |

| SL-800 | 3000KG/H | 200*200MM | 2~5cm | 40馬力 |

| SL-950 | 4000KG/H | 230*250MM | 2~5cm | 60馬力 |

| SL-1200 | 5000KG/H | 330*300MM | 2~5cm | 55kw |

| SL-1400 | 7000-8000KG/H | 400*400MM | 2~5cm | 90kw |

木材チップを効率よく作るには?

大量の木材チップを生産する機械をどのように選択するか?まず、SL-800以上の木材チップ製造機を選択できます。一方、大規模な設備は出力が大きく、他方ではコンベヤベルトに接続して時間と労力を節約できます。第二に、同じ効果を達成するために複数のSL-600ディスク木材チッパーを選択できます。第三に、ドラム木材チッパーを選択できます。これは産業用木材チップ装置なので、出力は非常に大きいです。

大型丸太チッパーの動画

分岐チップの応用

- 木材チップは直接販売することも、再処理のために製紙工場に送ることもできます。木材チップの品質を向上させるには、通常の木材を選択するか、 樹皮を剥いだ木 不純物の出現を減らすため。

- 切断した枝チップはバイオエネルギー燃料として利用できます。木材に必要な要件はなく、燃やすことができる限り、バイオエネルギープラントに送ることができます。

- 木材チップを連続的に炭化して木炭にすることもできます。 炭化炉.

Shuliy ウッドチッパーマシンの利点

当社は長年にわたり木材リサイクル機器の製造に携わっており、豊富な経験があります。強力なサプライヤーとして、当社のディーゼル枝チッパーには以下の利点があります。

- コンパクトな構造、絶妙な外観、洗練された耐久性のあるアクセサリー。

- ソリューションとカスタマイズされたサービスを提供します。

- 安全で便利な操作。

- 幅広い応用範囲と競争力のある価格。

- 低消費、高出力。

結論

ウッドチッパーは、木の枝や幹、その他の木くずを処理するための効果的な方法です。これらは、製材所やその他の木工業からの木材廃棄物を処理するためにも使用できます。ウッドチッパーは一般的に安全に使用できますが、製造元の指示に従い、耳や目の保護具を着用するなど、適切な安全対策を講じることが重要です。Shuliy Machineryは、包括的な木材リサイクル機械工場です。ウッドチッパー機械に興味がある場合は、専門家に連絡してできるだけ早くプロジェクトを開始してください。