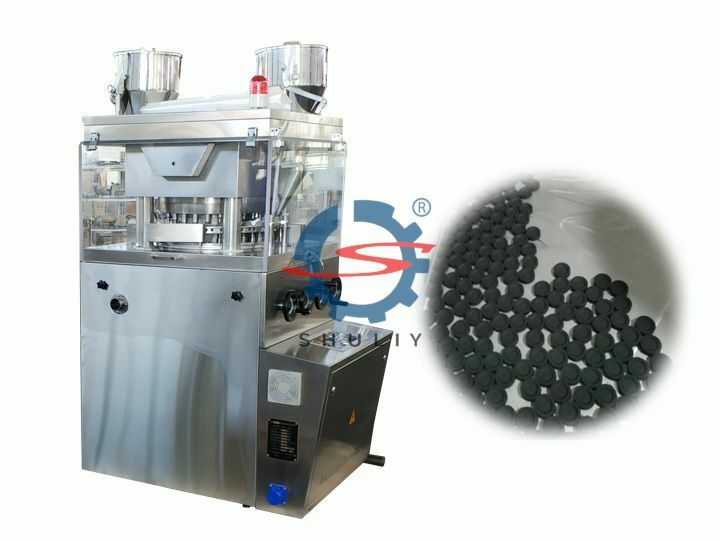

木炭ボールプレス機 | BBQ炭焼き機

| モデル | SL-BP290 |

| ローラーサイズ(mm) | 290*200 |

| 主軸回転数(r/min) | 12-15 |

| 電力(kw) | 5.5-7.5 |

| 能力(t/h) | 1-3 |

| 寸法(m) | 1.6*1.2*1.4 |

炭ボールプレス機は、石炭粉末またはバイオマス炭粉末からレンガを生産するためのツールです。枕、パン、球体など、さまざまな形の粉状ブリケットを生産できます。これらの完成品は、金属製造、発電所、窯、加熱、ケータリングなど、さまざまな産業で広く使用されています。したがって、その市場は非常に大きいです。Shuliy 石炭粉末ブリケット機の出力は1時間あたり5-10tです。したがって、さまざまな大規模工場の生産需要を満たすことができます。機械の価格についてお問い合わせください。大きな割引を受けることができます。

生 Mの材料 Cハーコール B全て P休む 機械

木炭ボール圧縮機は広く使用されています。原材料には、石炭粉、鉄粉、炭素粉、アルミニウム粉、石膏などがあります。さらに、鉄くず、スラグ、尾鉱、スラッジ、カオリンなどの廃棄物材料を使用することもできます。これらの原材料の細かさは5mm未満である必要があります。石炭粉や木炭粉などの木炭粉成形機の原材料は、バインダーで前処理する必要があります。(一部の原材料は接着剤を追加する必要がありません。詳細についてはお問い合わせください)。

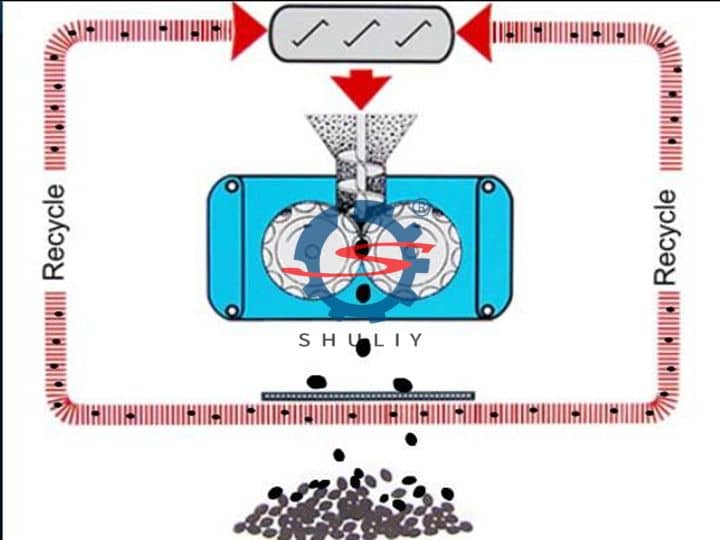

炭玉練炭機の構造

木炭練炭成形機には、主にホッパー、ギア、プレスローラー、コンベアベルト、モーター、スピードコントローラーなどの構造が含まれています。ギアのうち 2 つは 2 つのローラー金型を駆動します。加圧ローラーが互いに向かって移動するため、2 つの半球が完全な球を形成できます。

入口

木炭ボールプレス機の供給ポートにはスクリュー供給装置が付いています。一方で、供給速度を制御して炭素粉や石炭粉の蓄積を防ぐことができます。一方、湿った材料を成形機のローラーに連続的かつ均一に供給できることが保証されます。

圧力ローラー

ローラースキンはさまざまなスタイルで設計でき、さまざまな形状の練炭を製造できます。ローラーの強力な機械的圧搾により、材料は球状のカーボンブロックに素早く形成されます。

出口

完成した製品はベルトコンベア上に落下し、排出口から排出されます。そして、微粉炭練炭機の出口には鉄製のスクリーンがあります。スクラップと完成品を分別することができます。ふるいにかけられたスクラップは集められ、使用されます。

石炭粉ボールプレス機

乾燥粉末石炭プレスは、接着剤を添加せずに乾燥粉末を直接処理できる石炭プレス装置の一種です。製造原料には石炭粉、煙突灰、白灰、鉄鉱石粉、鉛粉などが含まれます。金属製圧力ボールは主に製錬業界で使用されます。乾式粉炭圧搾装置には 3 つのモーターが付いています。さらに、メインエンジン、油圧システム、コンベアベルトをそれぞれ制御できます。プレスボールの発色が良いため、種類も豊富です。そのため注文するお客様も多いでしょう。非常に優れた成形効果を発揮する油圧高圧装置です。

完成品 の 木炭ボールプレス機

炭素粉末成型機の形状は金型によって決まります。当社の工場では、枕型、球型、パン型などの型をお客様に提供することができます。さらに、お客様向けに金型パターンや文字をカスタマイズします。

のパラメータ BBQ炭ボールプレス機

加圧ローラーの径や幅だけでなく、お客様のニーズに合わせたカスタマイズも可能です。また、その型パターンとテキストもカスタマイズできます。

| モデル | ローラーサイズ(mm) | 主軸回転数(r/min) | 電力(kw) | 能力(t/h) | 寸法(m) |

| SL-BP290 | 290*200 | 12-15 | 5.5-7.5 | 1-3 | 1.6*1.2*1.4 |

| SL-BP360 | 360*250 | 12-15 | 7.5-11 | 3-5 | 2.1*1.3*1.76 |

| SL-BP430 | 430*250 | 12-15 | 15-18.5 | 4-7 | 2.3*1.53*1.9 |

| SL-BP500 | 500*300 | 12-15 | 22-30 | 5-10 | 2.6*1.75*2.1 |

| SL-BP650 | 650*350 | 10-13 | 37-55 | 8-13 | 3.42*2*2.2 |

| SL-BP750 | 750*380 | 10-13 | 45-75 | 12-17 | 3.7*2.55*2.6 |

| SL-BP850 | 850*460 | 10-13 | 75-110 | 15-20 | 3.9*2.6*2.7 |

| SL-BP1000 | 1000*530 | 10-13 | 110-132 | 20-30 | 4*2.8*2.8 |

炭の動画 バーベキュー 機械

下のビデオではバーベキュー用炭工場の製造工程をご覧いただけます。そして、その作業手順は非常に簡単です。そのため、炭焼き機の操作手順を簡単に理解することができます。

ローラーミネラルパウダープレス販売用

Shuliy 機械設備株式会社は、あらゆる種類の炭機械生産設備の製造を専門としています。当社の工場は、さまざまな石炭ブロック機の型を顧客に提供します。たとえば、楕円形、パン、枕、円柱、正方形、球体などです。当社は湿った材料用ボールプレスと乾燥した材料用ボールプレスを販売しています。さらに、乾燥機、ミキサー、 炭パッキング機なども販売しています。今すぐお問い合わせいただき、最新の炭ボールプレス機のリストを入手してください。