New Charcoal Making Machine | Continuous Carbonization Furnace

| Model | SL-05 |

| Capacity | 0.3-0.5t/h |

| Working Method | Fully continuous |

| Reactor Size | 820mm |

| Energy Consumption | 45kw/h |

| Dimensions | 28m*10m*6m |

| Weight | 28t |

| Operating Pressure | Slight negative pressure |

| Service Life | 5-8 years |

New charcoal making machine is a continuous carbonization furnace specially developed for carbonizing various biomass materials. The new design carbonization furnace is not only beautiful in appearance and atmosphere. And its console has added an intelligent numerical control panel. In addition, the carbonization rate of raw materials has also increased from the original 75% to 95%. In short, the new charcoal machine is low-carbon environmental protection equipment with high-cost performance and a high return rate. Contact us now for the latest consultation on it. For example, price, shipping. We look forward to a pleasant cooperation with you.

Raw materials for new design charcoal making machine

It can process biomass feedstocks with a size of less than 10cm. Its raw materials are agricultural and forestry waste (rice husk, wood pellet, straw pellet, bark), fruit shell (coconut shell, olive fruit, palm shell, chestnut shell, longan shell), and others (cow dung, cow bone, sludge), etc. As the raw material moisture is smaller, the carbonization rate is higher. Therefore, we will recommend customers choose a tumble dryer to dry raw materials. The dryer can keep the raw material moisture at about 8%.

Structure of the new charcoal making machine

Double main furnace

The carbonization main body of the carbonization furnace adopts a double-cylinder structure. This design makes the material tumbling from the inner furnace to the outer furnace in a circle. That is to say, the inlet and outlet of the coconut shell carbonization furnace are on the same side.

Combustion chamber

The combustion chamber is insulated with thermal insulation rock wool. It is also a closed furnace body. Therefore, the airtightness of the whole machine is good, and the carbonization efficiency is high. The heating material of rice husk carbonization furnace can be charcoal, wood, diesel, natural gas, liquefied petroleum gas, biomass, etc.

PLC control panel

The starting and control system was changed from the previous power distribution cabinet to the plc touch screen mode. Customers can set the speed, temperature, time, etc. through the computer.

Furnace reinforcement

The surface of its furnace body is reinforced with horizontal and vertical carbon steel metal. The furnace body is wrapped in a stainless steel casing. Therefore, the use of the new coconut shell charcoal making machine is not easy to deform and has a longer life.

Video of biomass continuous carbonization furnace

Below is a video of processing various feedstocks with a biomass carbonization furnace. You can see its efficient and high-quality charring from the video.

Parameters of the new design charcoal making machine

The time and temperature of carbonization of different raw materials are different. Therefore, the following data are for reference only.

| Model | SL-05 | SL-10 | SL-30 | SL-50 |

| Capacity | 0.3-0.5t/h | 0.8-1t/h | 2.5-3t/h | 4.5-5t/h |

| Working Method | Fully continuous | |||

| Reactor Size | 820mm | 1000mm | 1300mm | 1700mm |

| Energy Consumption | 45kw/h | 65kw/h | 90kw/h | 125kw/h |

| Dimensions | 28m*10m*6m | 33m*13m*7m | 40m*15m*8m | 50m*16m*10m |

| Weight | 28t | 35t | 45t | 54t |

| Operating Pressure | Slight negative pressure | |||

| Service Life | 5-8 years |

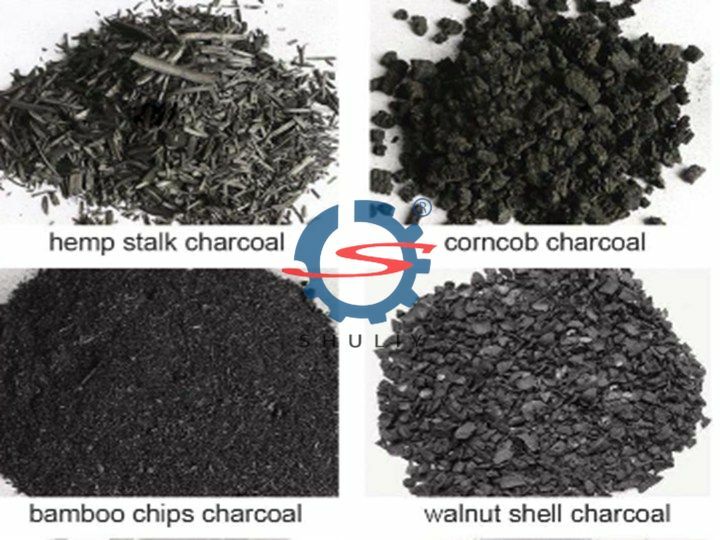

Finished products of bio charcoal

The finished products of this excellent continuous carbonization furnace can be various, such as coconut shell charcoal, sawdust charcoal, palm kernel shell charcoal, bamboo charcoal, rice husk charcoal, and nut shell charcoal, etc.

Working principle of the charcoal carbonization furnace

The carbonization process involves heating the organic material in an oxygen-limited environment. As the material is heated, it begins to break down and release volatile gases. These gases are then burned off, leaving behind a solid residue of carbon, which is known as charcoal.

Applications of continuous carbonization furnace

Continuous charcoal carbonization furnaces are commonly used in the production of activated charcoal, which is a form of charcoal that has been treated to increase its surface area and make it more porous. Activated charcoal has a wide range of applications, including water treatment, air purification, and chemical separation.

In addition to their use in the production of activated charcoal, continuous charcoal carbonization furnaces are also used in a variety of other industries, including the production of fuel, the manufacturing of chemicals, and the treatment of waste materials.

Conclusion

Overall, the continuous carbonization furnace is an essential piece of equipment that plays a key role in the production of activated charcoal and other forms of charcoal. Its ability to operate continuously allows for efficient and reliable production, making it an important tool in a wide range of industries.

Shuliy group is a professional charcoal carbonization furnace manufacturer. We provide a full range of carbonization machines to meet your specific requirements. Welcome to contact our experts to start your business as soon as possible.