5t/h Pillow charcoal briquette machine for the UK

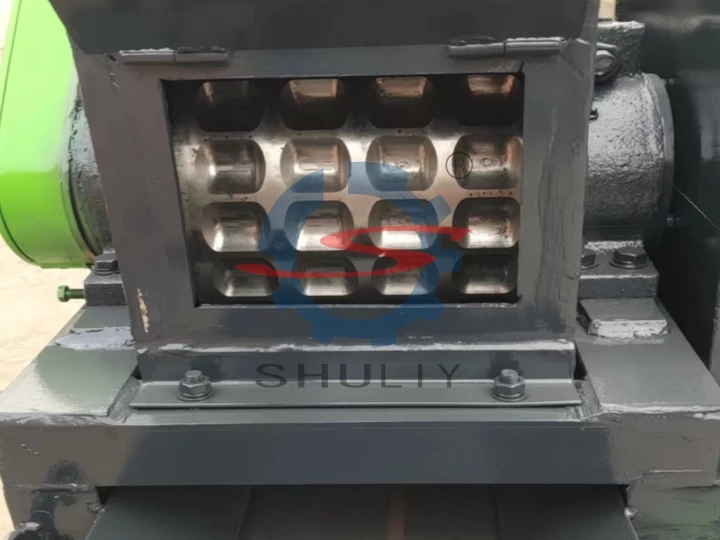

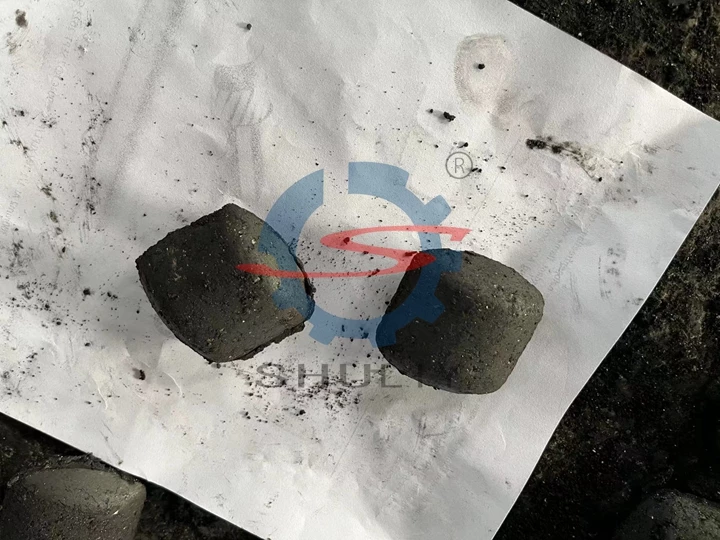

Small charcoal processors in the UK are in urgent need of efficient production equipment due to the sharp increase in demand for BBQ charcoal. Shuliy factory customized the SL-360 pillow charcoal briquette machine according to customer’s demand, producing 3-5 tons per hour, with special molds in 5cm diameter pillow shape.

UK customer profile

A small charcoal processing plant in the UK, specializing in a wide range of barbecue and cooking charcoal, has been growing steadily in the local market in recent years.

The factory sources raw charcoal briquettes from neighboring charcoal suppliers, including bamboo charcoal, wood charcoal, and even coconut shell charcoal, which is then finely ground into powder, skillfully formulated with binders, and carefully extruded through a molding process before being dried and packaged for market.

Why choose to buy a pillow charcoal briquette machine?

With the prevalence of outdoor barbecue culture, the market demand has increased dramatically, making this factory orders surge, the urgent need to enhance production capacity. In order to meet the demand for large-scale production, the factory manager decided to introduce a high-performance barbecue charcoal molding machine. After several rounds of selection and comparison, the Shuliy factory stood out with its professional technology and good reputation.

Shuliy’s solution for the UK charcoal factory

Shuliy recommended the SL-360 BBQ pillow charcoal briquette machine, which can produce 3 to 5 tons per hour, and is perfectly suited to the customer’s current and future expansion plans. In addition, Shuliy’s factory also customized the mold to meet the customer’s specific needs, designing a pillow-shaped charcoal briquette with a diameter of 5 cm, which is both aesthetically pleasing and practical, in line with the market’s preference.

Client is satisfied with the program and pays a 50% deposit

After understanding the details of the machine parameters, mold design, and delivery lead time, the UK customer was deeply satisfied with Shuliy factory’s professional services and customized solutions and did not hesitate to make a 50% advance payment to show their determination to cooperate.

At present, this carefully customized SL-360 pillow charcoal briquette machine is already in intense and orderly production and is expected to cross the ocean and arrive in the UK soon, helping this small charcoal product processing factory to step into a new chapter of large-scale and standardized production, and jointly promoting the prosperous development of the UK barbecue charcoal market.