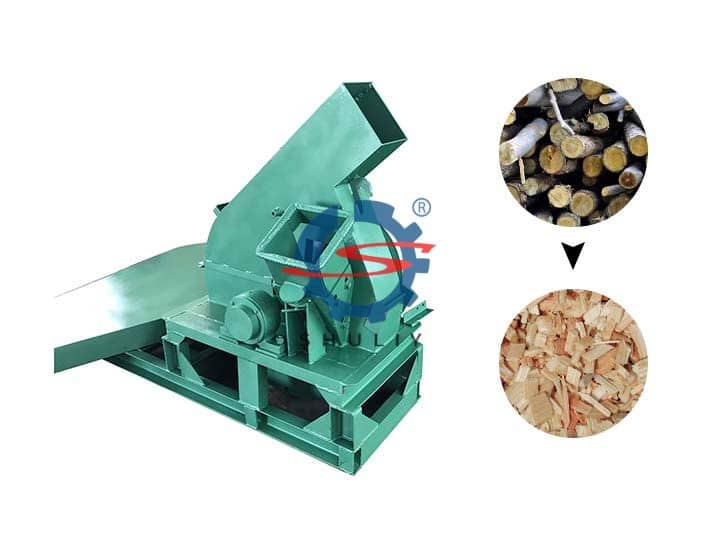

Hammer Mill | Wood Wastes Grinder

| Model | SL-HM60 |

| Power(kw) | 22 |

| Hammers(pcs) | 30 |

| Dust remover(pcs) | 5 |

| Cyclone diameter(m) | 1 |

| Capacity (t/h) | 0.6-0.8 |

Hammer Mill is an enhanced version of the wood shredder. Because it can process the raw materials very delicately. More importantly, it can handle a wide range of raw materials. Such as paper, coconut shells, twigs, medicinal materials, plastics, etc. Thus, it is a must-chosen machine in some recycling production lines. At the same time, t is also one of the most profitable projects. Shuliy hammer milling machine has the characteristics of high quality, good performance, high efficiency and energy saving, and a wide range of applications. Start your business now and we will give you a big discount.

Raw materials for hammer mill

Commercial hammer mills are more widely used than ordinary wood crushers, with higher output and more types of finished products. The raw materials it can handle can be divided into the following categories.

- Wood materials: logs, wood chips, wood board, branches, bamboo, poplar, fruit trees, etc.

- Grains: corn, wheat, sorghum, buckwheat, soybean, etc.

- Charcoal: raw charcoal, bamboo charcoal, fruit charcoal, coconut shell charcoal, etc.

- Fibers: rice straw, straw, wheat straw, cotton and hemp straw, etc.

- Others: cardboard boxes, coconut shells, Chinese herbal medicines, forages, etc.

Operating principle of wood wastes grinder

The main working principle of the hammer mill is that the high-speed rotating rotor drives the hammer of the main shaft to rotate at high speed. Once the raw material passes through the hammer, it will be crushed immediately. Therefore, it is a crushing device that works sustainably.

Video of hammer crusher crushing

Hammermill has a powerful crushing force. Therefore it can further process the finished wood chipper and wood shredder. Through the video, you can clearly see the advantages of its high efficiency and easy operation.

Composition of hammer mill

Wood hammer mill is a high-speed crushing machine. It mainly includes accessories such as gaskets, hammers, Induced draft fan, and screens.

Screen and hammer

The number of hammers of the wood waste grinder determines the amount of feed, that is, its model size. The diameter of the screen mesh determines the fineness of the final material.

Discharging device

Hammer mill has two kinds of discharge devices: screw discharge and Shaclon discharge. And the combination of the two can improve the output quality.

Finished product of various sizes

Hammer mills can produce different sizes of fineness. Generally, the hammer mill can feed the powder and then discharge it, which can be continuously produced in large quantities. Wood is most commonly processed to a size of 3mm sawdust. There are also wood chips processed to 6-8mm for reprocessing and sale. And charcoal is generally processed to 3mm charcoal powder.

Application of Industrial hammer milling machine

- Charcoal production line

Hammer mills are widely used in charcoal production lines. Provide raw materials for the production of biomass briquette. It can also directly crush charcoal to produce charcoal briquette. - Animal Feed

It hammers forage and grain into powder. So customers can use these materials as feed. - Nutrients

Sawdust is used as soil fertilizer to increase soil fertility. What’s more, it can also be used as a medium to grow fungi. - Papermaking

After the wood shredder shreds the paper, it can be reused for papermaking.

Wood waste grinder for sale

Shuliy Machinery Equipment Co., Ltd. is the top wood recycling equipment manufacturer in China. We sell electric wood wastes grinders, diesel hammer crushers, and electric diesel hybrid wood wastes grinders. This hammer crusher is versatile and can handle different raw materials. So you can choose different models boldly. We will also customize the feeding port, discharging method, and mobility of the equipment. Call or email us for more product information.

Hammer crushing machine parameters

| Model | SL-HM60 | SL-HM70 | SL-HM80 | SL-HM90 | SL-HM1000 | SL-HM1300 |

| Power(kw) | 22 | 30 | 37 | 55 | 75 | 90 |

| Hammers(pcs) | 30 | 40 | 50 | 50 | 105 | 105 |

| Fan(kw) | 7.5 | 7.5 | 11 | 22 | ||

| Dust remover(pcs) | 5 | 5 | 5 | 5 | 14 | 14 |

| Cyclone diameter(m) | 1 | 1 | 1 | 1 | 1 | 1 |

| Capacity (t/h) | 0.6-0.8 | 1-1.2 | 1.2-1.5 | 1.5-3 | 3-4 | 4-5 |

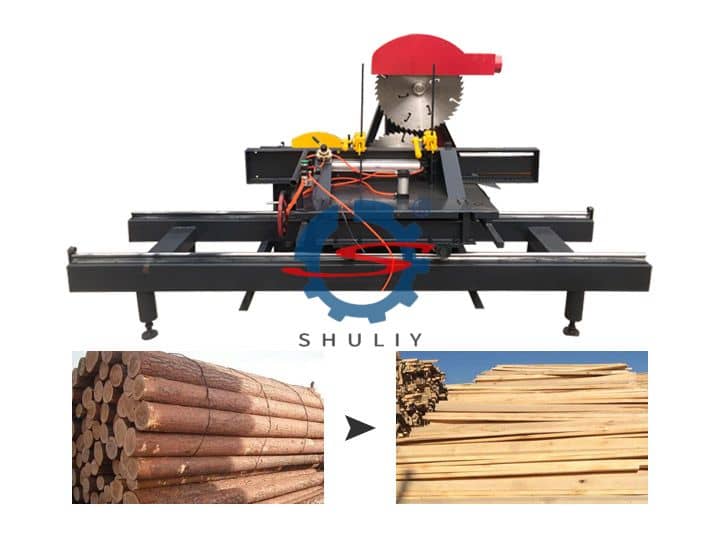

The difference between hammer mill and wood crusher

Firstly, raw materials.

The raw materials processed by the hammer mill are wide and small. The raw material of the wood crusher is single and large.

Secondly, structure.

The structure of the former mainly consists of gaskets, hammers, and screens. The latter structure mainly consists of cutter head, hammer head, and screen.

Thirdly, broken strength.

The crushing force of the former is greater than that of the latter. That can be said to be a refined treatment of the latter’s finished product.