Charcoal Production Line

| Brand | Shuliy |

| Raw material | Log, bamboo, sawdust, rice husk, coconut, etc |

| Warranty | One year |

| Note | Custom service available |

Charcoal making machine production line is a process of making log, bamboo, biomass briquette, and other raw materials into charcoal through the steps of crushing, drying, briquetting, and carbonization. Due to the high hardness, long burning time, and non-polluting characteristics of machine-made charcoal, it has set off an upsurge in the world. We will provide customers with flue gas purification equipment to ensure that customers produce within the environmental protection index. A sawdust briquette charcoal production line is an easy and profitable investment. Therefore, if you want to invest in charcoal machine equipment, you are welcome to inquire. Contact us now for the latest equipment parameters.

Charcoal making machine workflow

The process of the charcoal production line is very simple. It mainly includes the following steps: crushing – drying – briquette – carbonization. And there is a conveying device connection between each step. Therefore, customers of the charcoal factory do not need to invest a lot of manpower, 3-5 people can carry out production.

Charcoal production line structure

The corresponding equipment for the work process of the charcoal making machine is a wood shredder, sawdust dryer, biomass briquette machine, and carbonization furnace. These pieces of equipment are the basic equipment for making charcoal.

1. Wood shredder (crushing)

The wood shredder is a device that breaks some branches, waste solid wood boards, bamboo, and other raw materials into small wood chips. Because the size of wood chips required to make charcoal is 3-5mm. Therefore, wood shredders are very important.

2. Sawdust dryer (drying)

Because the production of biomass rods requires the humidity of the sawdust. Therefore, the customer should choose a sawdust dryer to reduce the humidity of the sawdust to about 10%. This step also guarantees the quality of the charcoal produced. Our factory provides rotary dryers and airflow dryers. In addition to fuels such as wood and coal, their heat source furnaces can also be heated by natural gas.

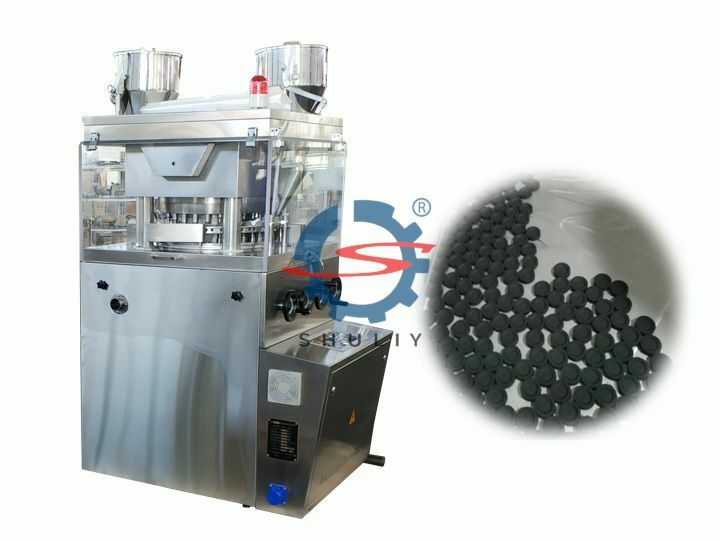

3. Biomass briquette machine (rod making)

The biomass briquette machine can turn the dried sawdust into hollow wooden sticks. It is one of the core equipment in the charcoal-making machine. The quality of charcoal depends on the biomass rod itself. Therefore, when using the sawdust briquette machine, the machine must be debugged first. Shuliy factory will send technicians to assist and guide.

4. Carbonization furnace (carbonization)

This is the last step of the whole process. We provide vertical carbonization furnace and horizontal carbonization machine. They can carbonize raw wood, bamboo, fruitwood, and other materials. The vertical carbonization furnace adopts internal and external double-tank technology. Therefore, it can better meet the large charcoal output and is convenient and flexible.

Three systems of charcoal making machine

Feeding system

Because of the small shape and loose characteristics of sawdust, the feeding system in the charcoal making machine chooses a screw feeder. It is characterized by closed and uniform feeding. We have U-shaped and round pipes. The U-shaped pipe is designed to be detachable. Therefore, it is also more flexible.

Dust removal system

On the one hand, it can collect sawdust and dust separately to ensure a hygienic environment in the factory. On the other hand, it also plays a role in cooling the material. It includes shaken, pipes, dust bag, and induced draft fan.

Purification system

The purification here is mainly for the flue gas produced during the processing of the raw materials of the charcoal making machine. Because of the high-temperature operation in the charcoal production line, the production of flue gas during the production process is inevitable. There are strict international factory flue gas emission standards. Fortunately, our smoke removal system can effectively eliminate smoke.

For dryers and carbonization furnaces, we provide smoke removal tanks. We provide fume removal hoods for rod making machines. Both smoke removal cans and smoke removal hoods can be combined with high-voltage electrostatic devices to achieve the best smoke removal effect.

Auto charcoal making factory features

1. High degree of automation and labor-saving.

2. Energy saving and environmental protection.

3. Good quality, simple operation, and stable performance.

4. Easy access to raw materials, low investment, and high return.

5. The output is large, and the demand for finished products is large.

6. Affordable price, many specifications.

5t charcoal processing line machine recommendation

The following equipment is added to the basic structure of the charcoal briquette machine for reference.

Crusher

If your raw material is large logs, we recommend that you choose drum chippers and hammer mills. These two machines are high-efficiency crushing equipment with large output. If your raw material is wood chips, we recommend that you choose a roller screen. The raw materials are transported by the conveyor belt to the roller screen to screen out 3-5mm sawdust.

Screw feeder

Its function is to evenly distribute the sawdust to the sawdust rod making machine. Its size depends on the number of rod making machines you choose. Therefore it is customizable.

Smoke removal hood and mesh belt conveyor

Because the temperature is too high when the biomass rod is processed, it is necessary to choose a metal conveyor belt for transportation. On the one hand, the mesh belt conveyor can transport the wooden sticks dropped from the stick making machine. On the other hand, it can dissipate heat from the wooden rod. The fume removal hood mainly includes a fan and a water tank. It is installed above the mesh belt to directly suck the smoke generated by the rod-making machine.

Features of sawdust briquette charcoal

Compared with coal, tree branches, straw, and other fuels, machine-made charcoal produced by charcoal machine not only has a high output but also has a large demand. It is more accepted by people. Machine-made charcoal has the following advantages:

1. Good quality, high sales, and good income.

2. Safe and pollution-free.

3. High calorific value and long burning time.

4. The appearance is beautiful and diverse.

Sawdust briquette making machine for sale

Shuliy Machinery is a specialized manufacturer of charcoal extruders. We sell wood crushers, sawdust dryers, screw conveyors, sawdust rod making machines, and so on. Moreover, we will provide design solutions for your production line. Therefore, welcome to learn about our products. We will provide you with competitive prices.

Our services

- We can provide customers with charcoal production line solutions with different yields of charcoal.

- We help customers to install the machine and test the machine for free.

- Our factory can design drawings for customers.

- Customers can also buy parts from us at any time.

Contact us to start your charcoal making business!

In addition to the machinery and equipment, a charcoal production line will also require a team of skilled workers to operate the machinery and oversee the production process. Quality control measures will also be in place to ensure that the final product meets the necessary standards. Shuliy Machinery is a professional charcoal making machine factory. There is a strong capability of researching, designing, manufacturing, and installing. Welcome to contact our experts to start your project as soon as possible.